The Making of Goby - The world's loudest direct to consumer toothbrush

Never making a noise sensitive product with moving parts. I think I'll just stick to handheld cheese jizzing guns. As the son of two doctors and a child of modern TV dramas; Occam's razor has been a staple in my problem solving process. Of course the simplest solution is the answer, but I think that only work for Dr. House. This project has introduced a new problem solving principle into my life: Hickam's dictum. Meaning "Patients [or products] can have as many diseases as they damn well please" Again never making a product with complex moving parts.

Teardown

Brush Head

Off Handle

ON handle

Gear Train Subsystem test 1

The gear system was a complete unknown, totally beyond my competence and a pain in the ass to prototype. The fist gear system below was a 4:1 scale of a basic 4 bar linkage driven by a 120rpm gear motor. It's intent was a simple engineering exercise the mechanics of the system outside of SolidWorks. The prototype was designed around amazon prime's motor selection and my Stratsys Uprint's dissolvable support limits. The system looks super clunky and goofy

Gear train 1:1 scale test

After the larger 3D printed prototype I felt confident enough to build a 1:1 CNC'd prototype. The gearing and linkages are all 1:1, but the motor was a 12,000 RPM motor with an encoder to record RPM. This is almost the exact geometry that went into the final product.

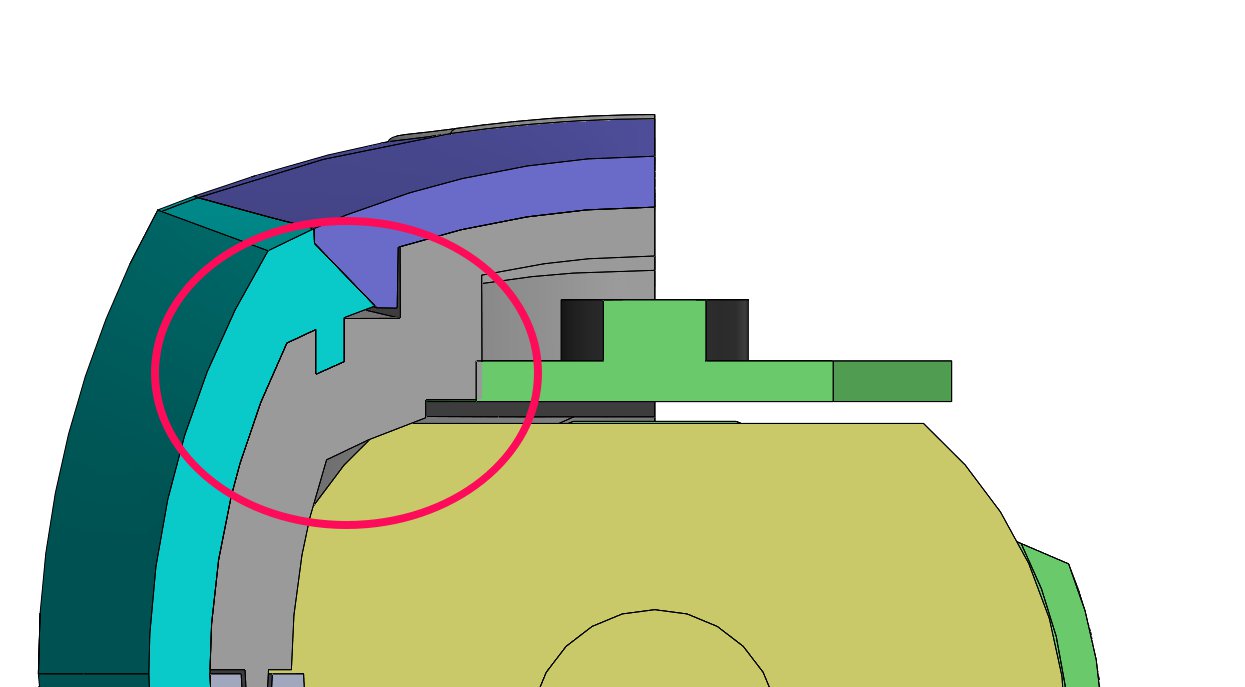

Housing the gear system

CAD CAD CAD

fuck this sucks

The CAD has been rebuilt so many fucking times. The master part is now 500 features.... never doing this again

Pre China Prototypes

The color balance is complete shit