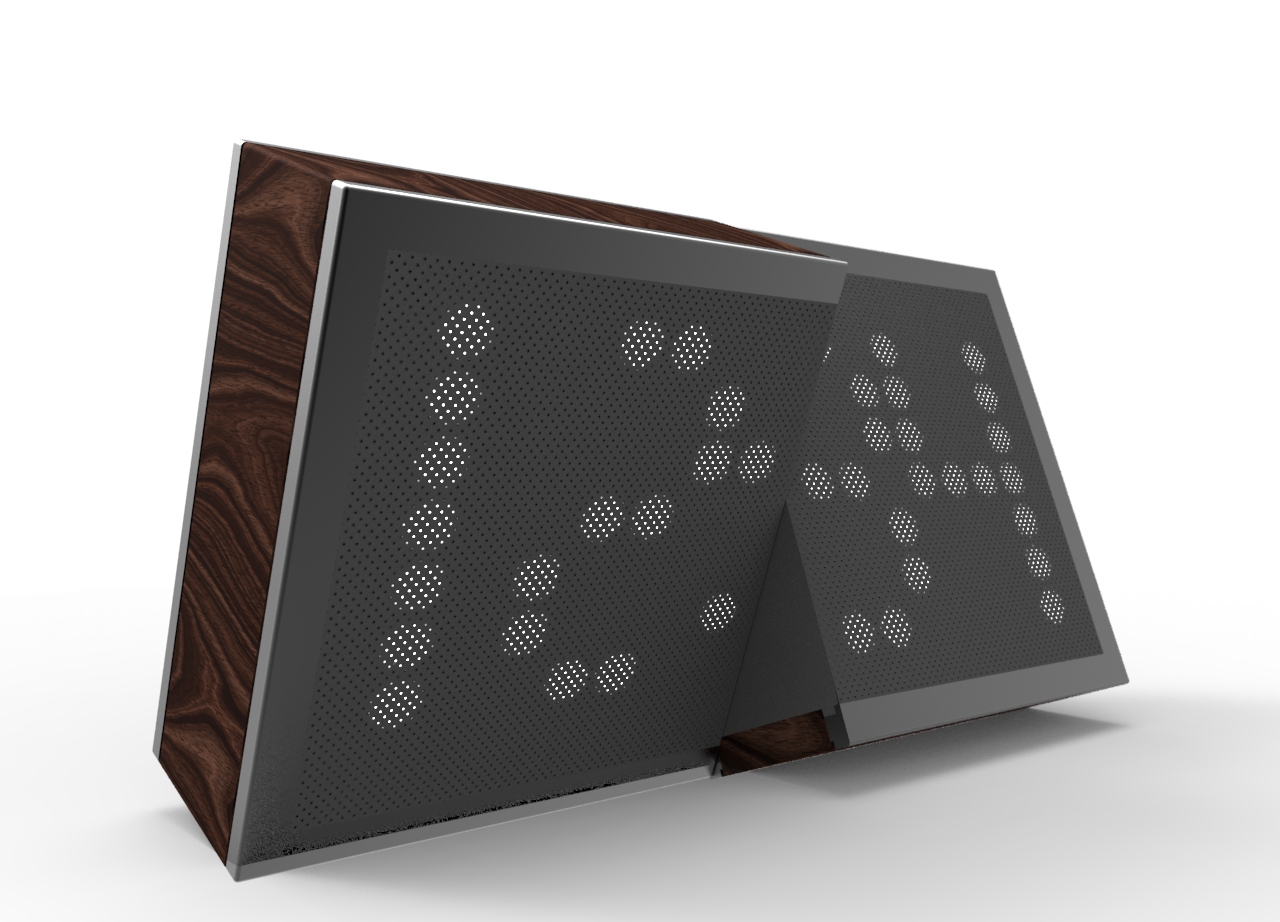

IT'S A CLOCK OR SOMETHING

This page documents our journey through the past 15 weeks of the development cycle. The PDI Capstone class gave us the opportunity to pursue the clock project.

Weeks 1: Planning

We started by planning out the semester. From the chat below you can see we had ambitions goals many of them we never reached.

Week 2: Design

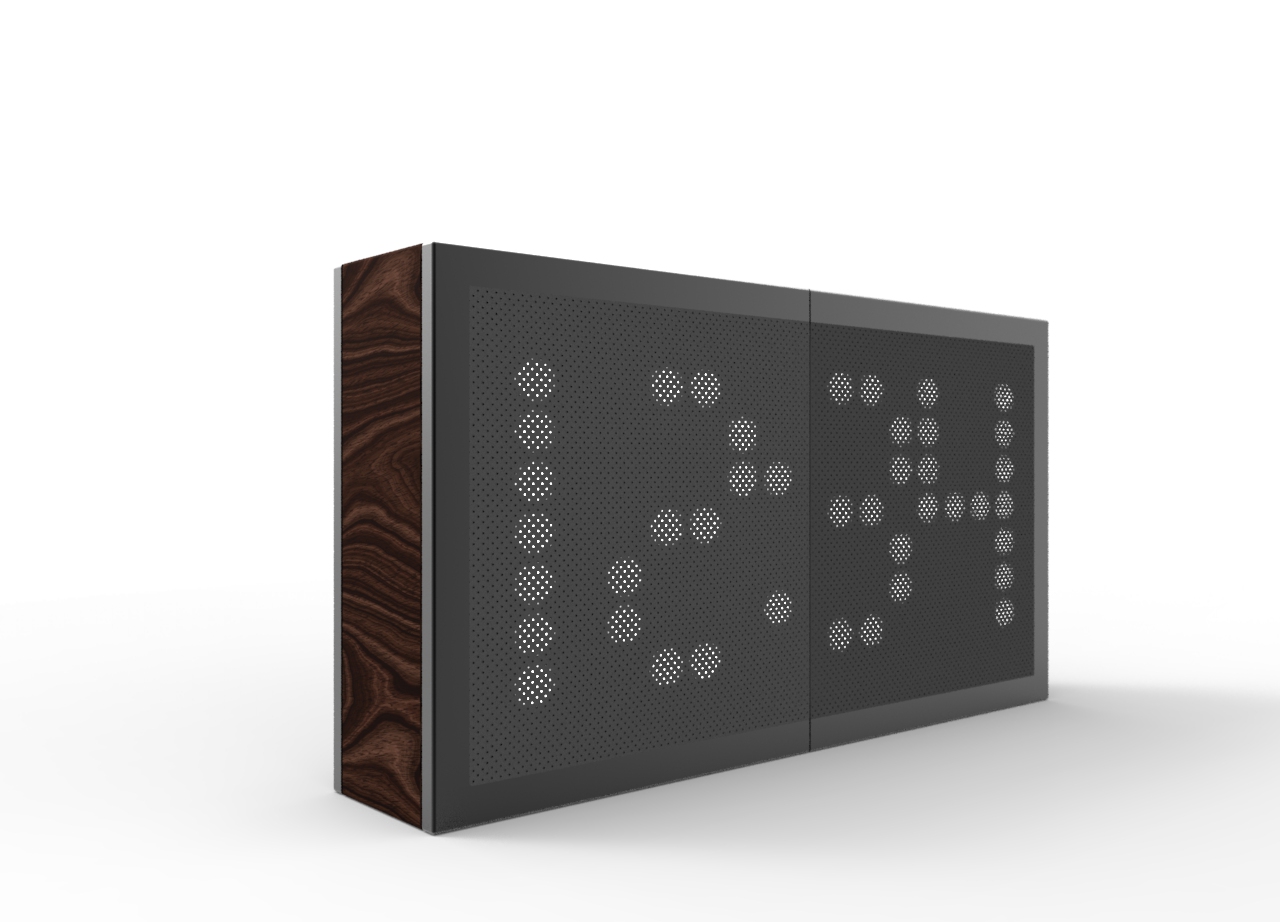

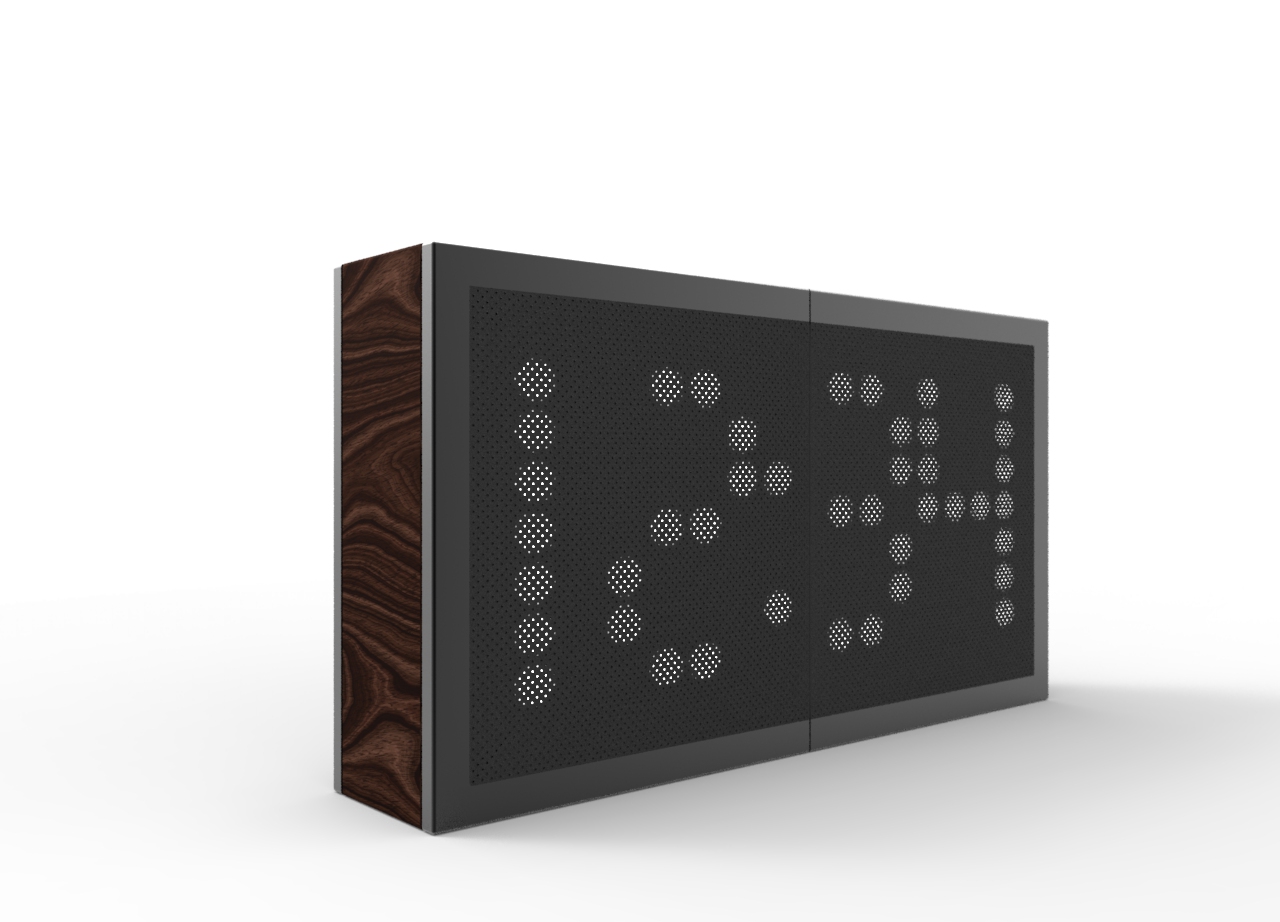

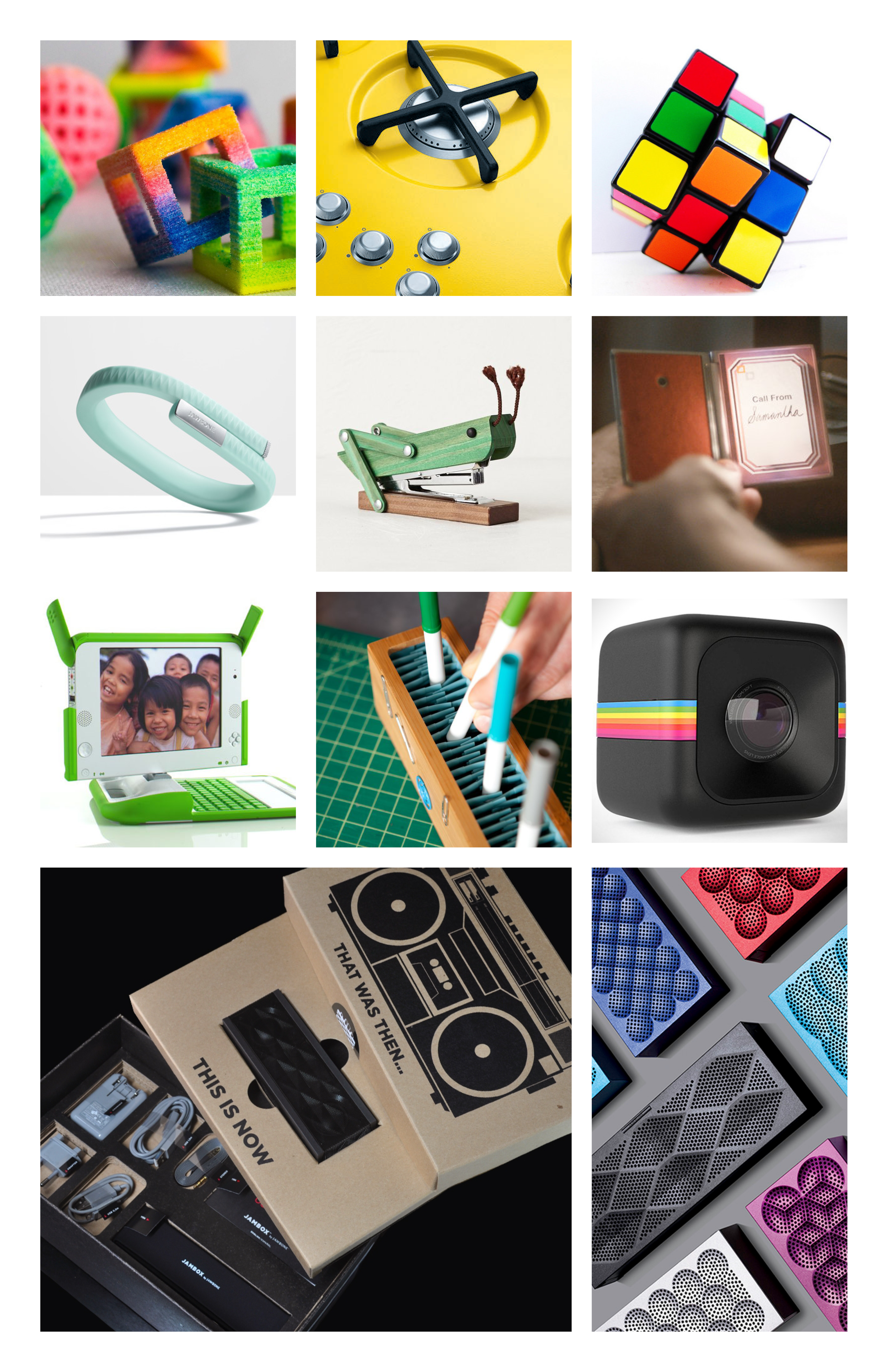

From the start we know the look and feel of the product had to change, but how it had to change was a mystery. We began by compiling products that evoked certain feelings into inspiration boards.

WOOD AND LEATHER

SIMPLE

Week 4: Still Designing...

FUN

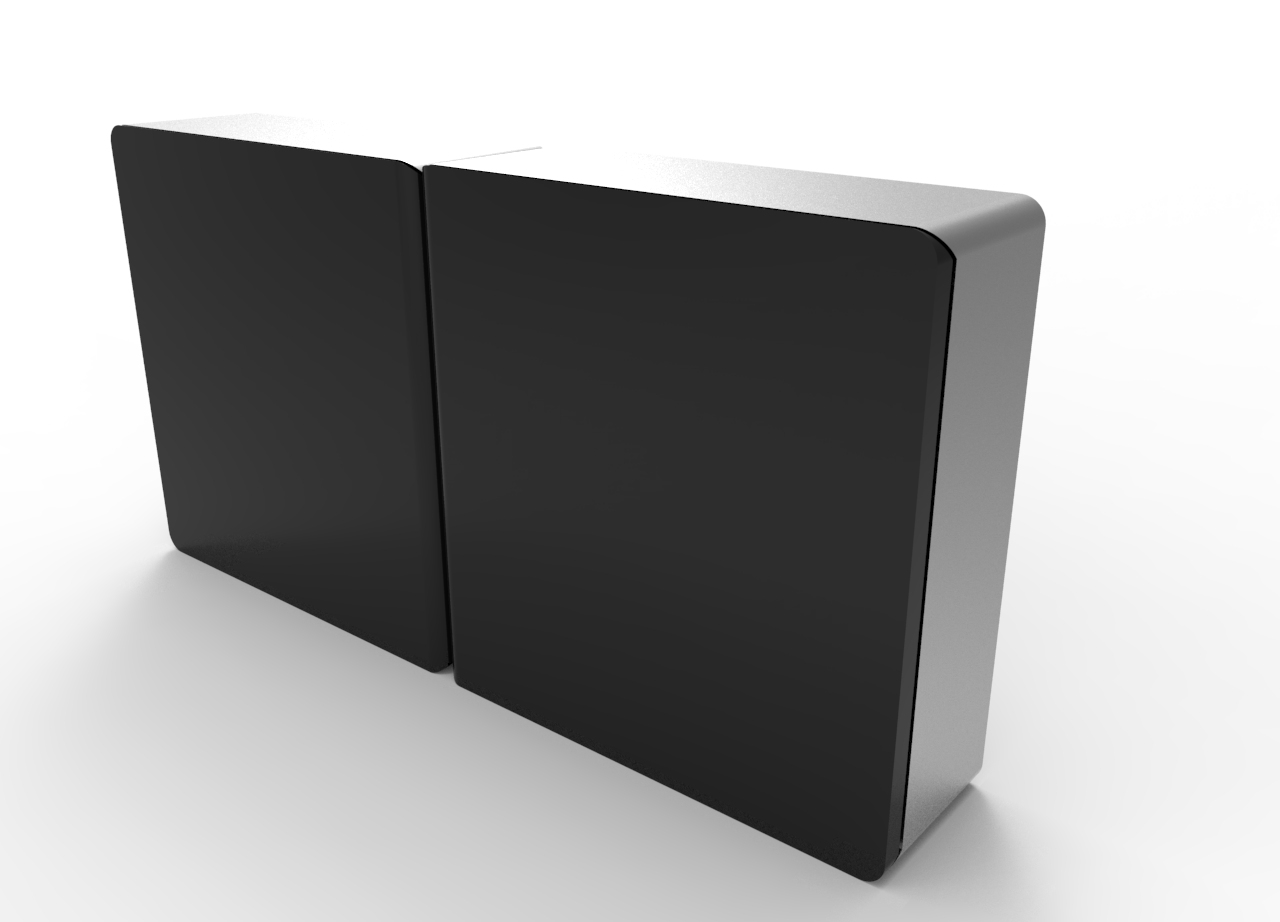

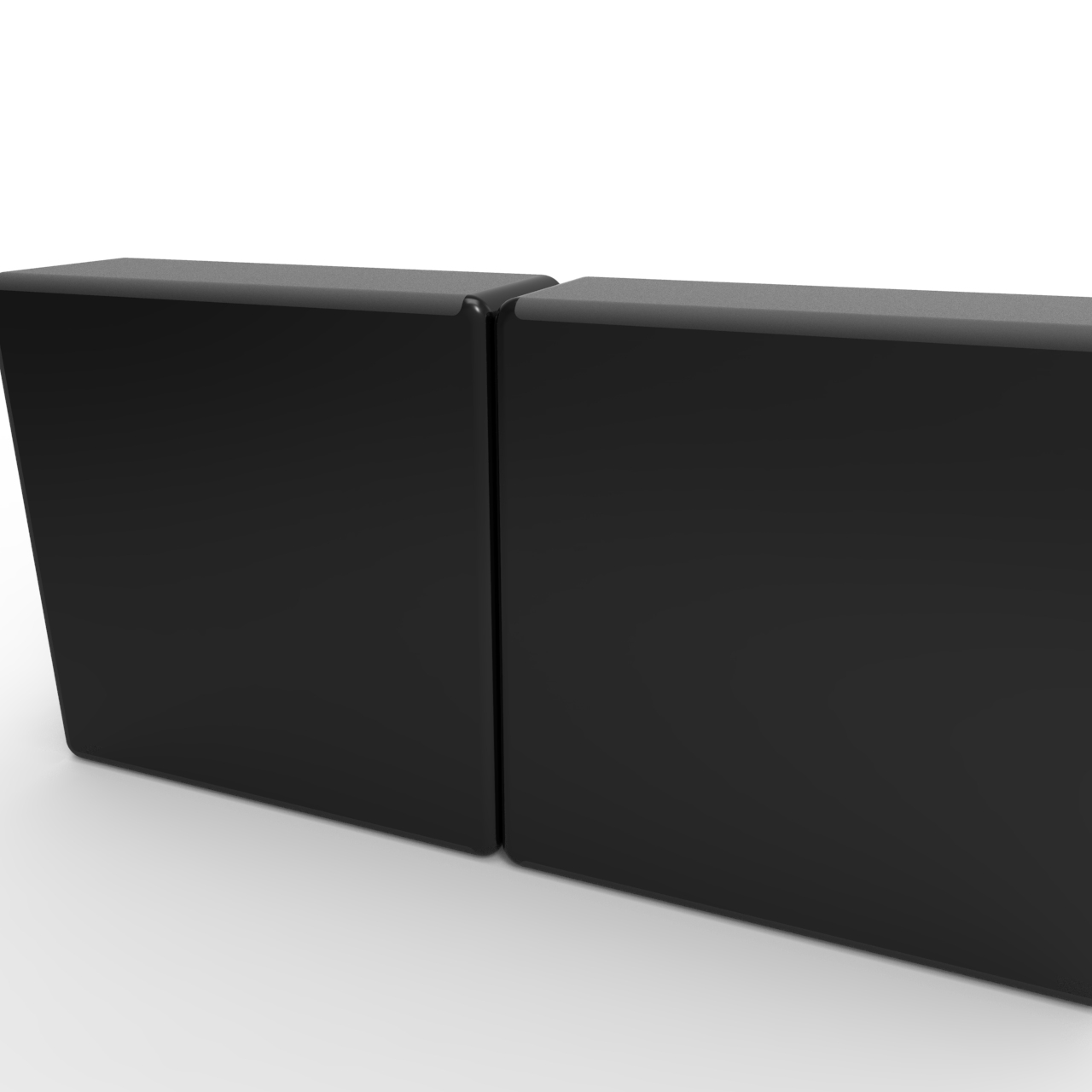

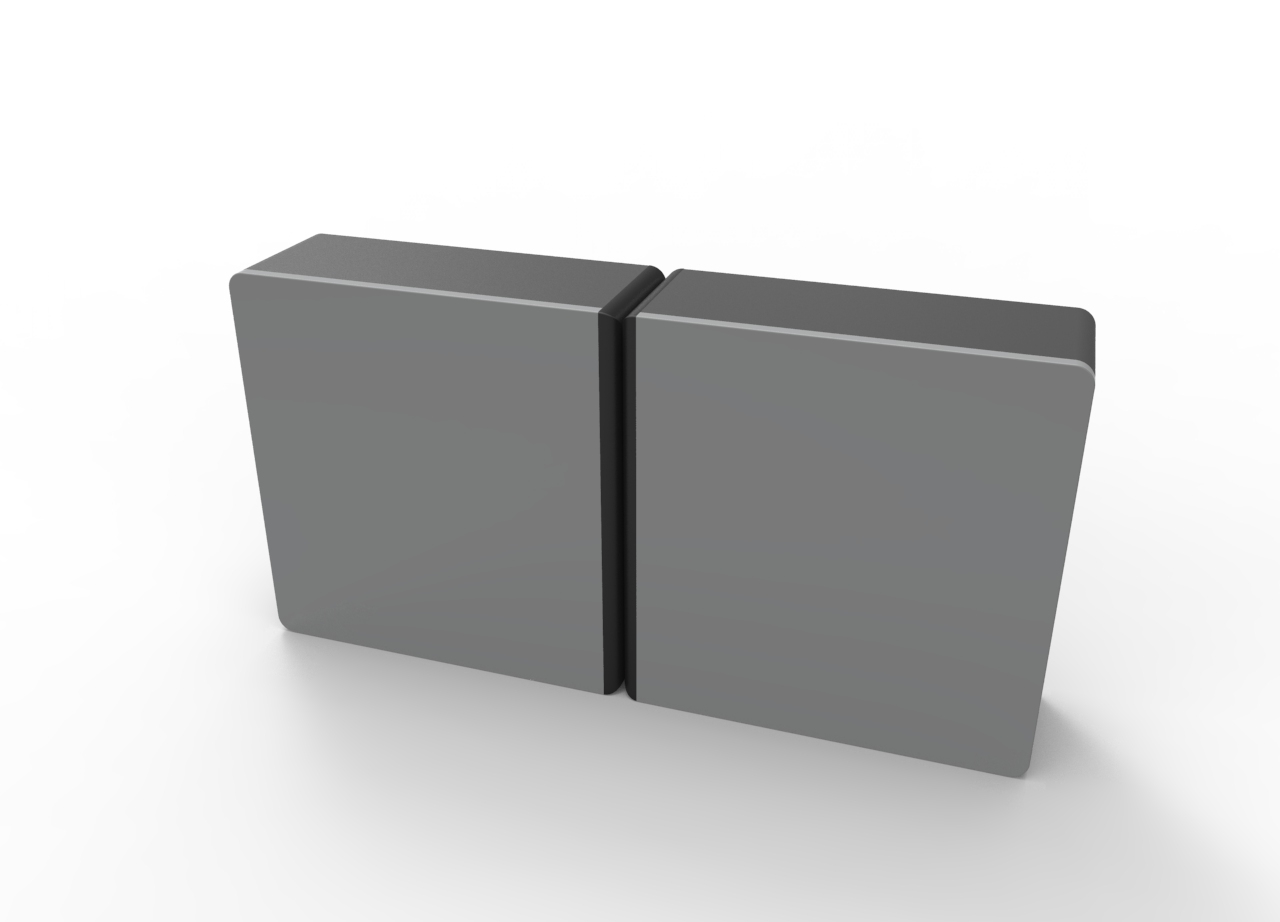

After looking at these products I noticed to use of rounds and patterns to express touchability and friendliness, so we began to experiment with different types of rounds.

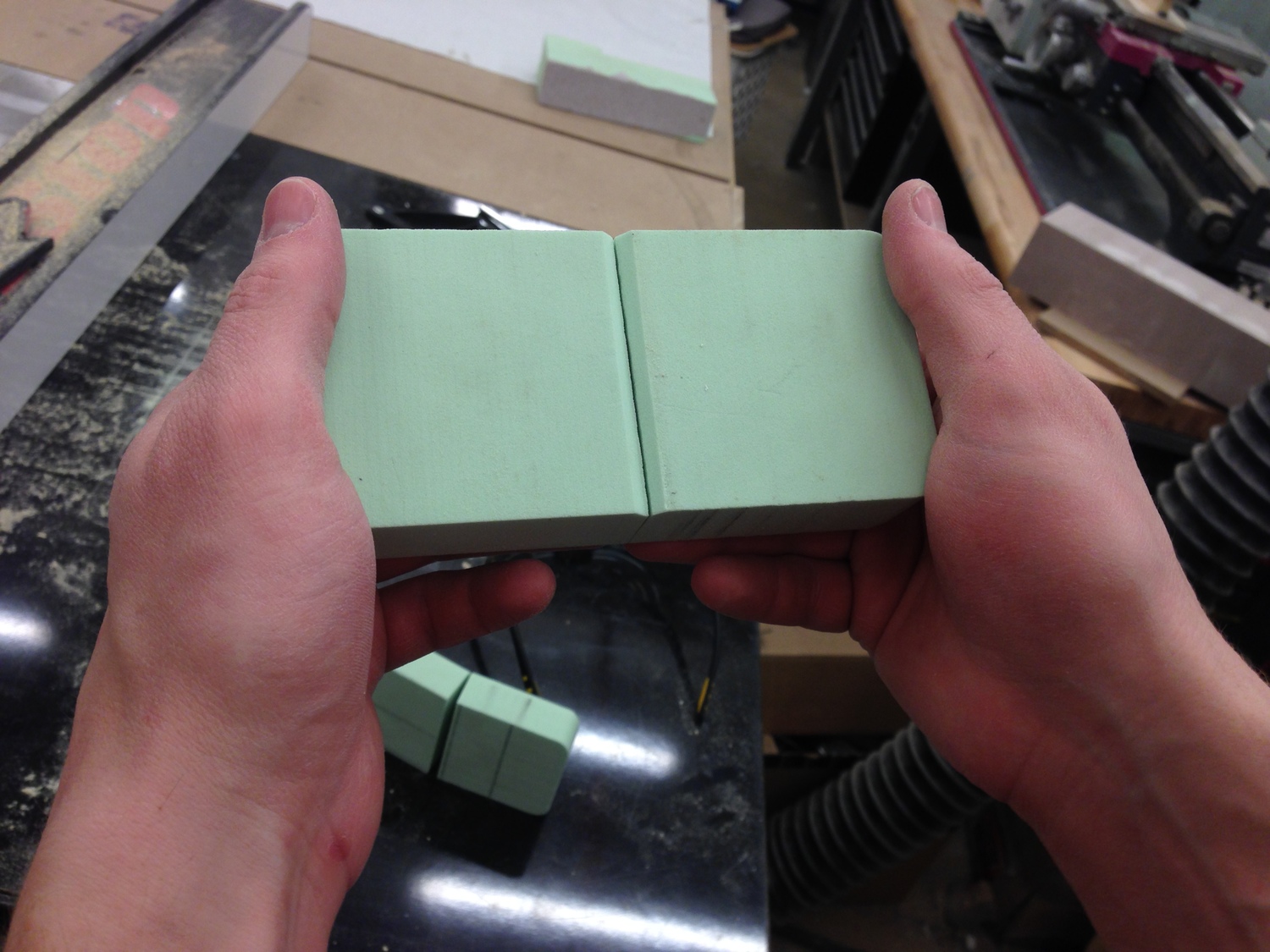

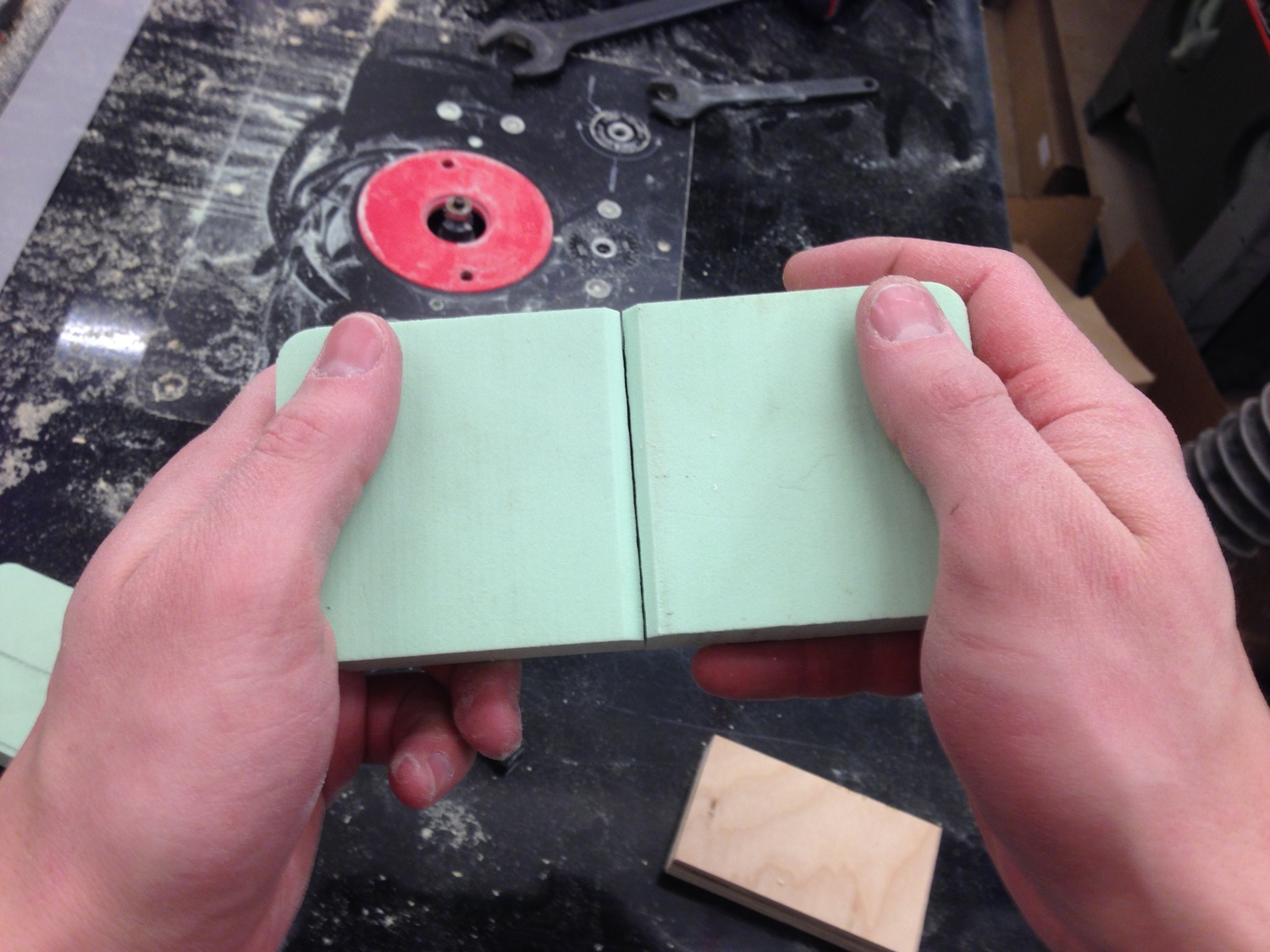

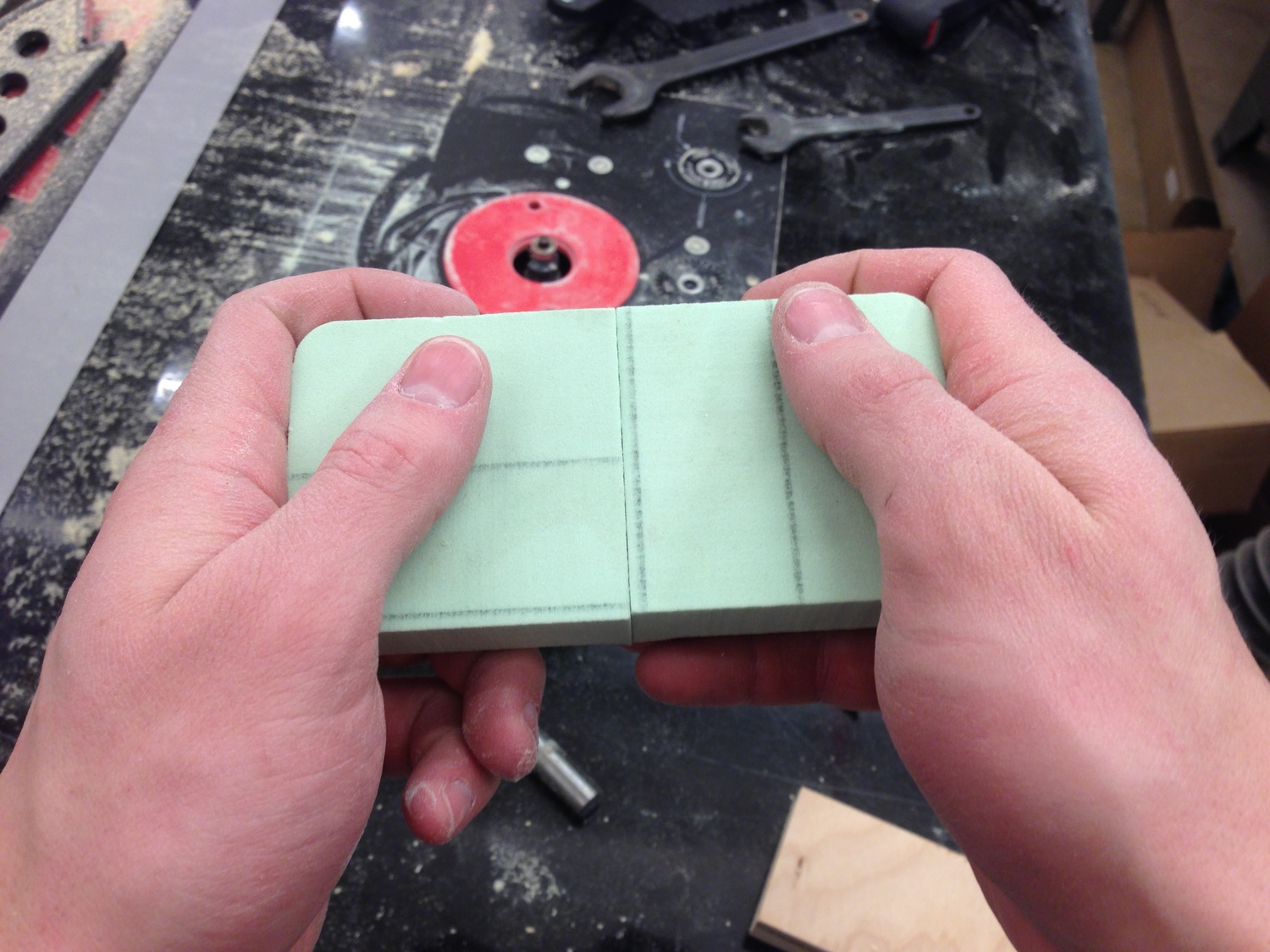

Week 5: Designing a Feel

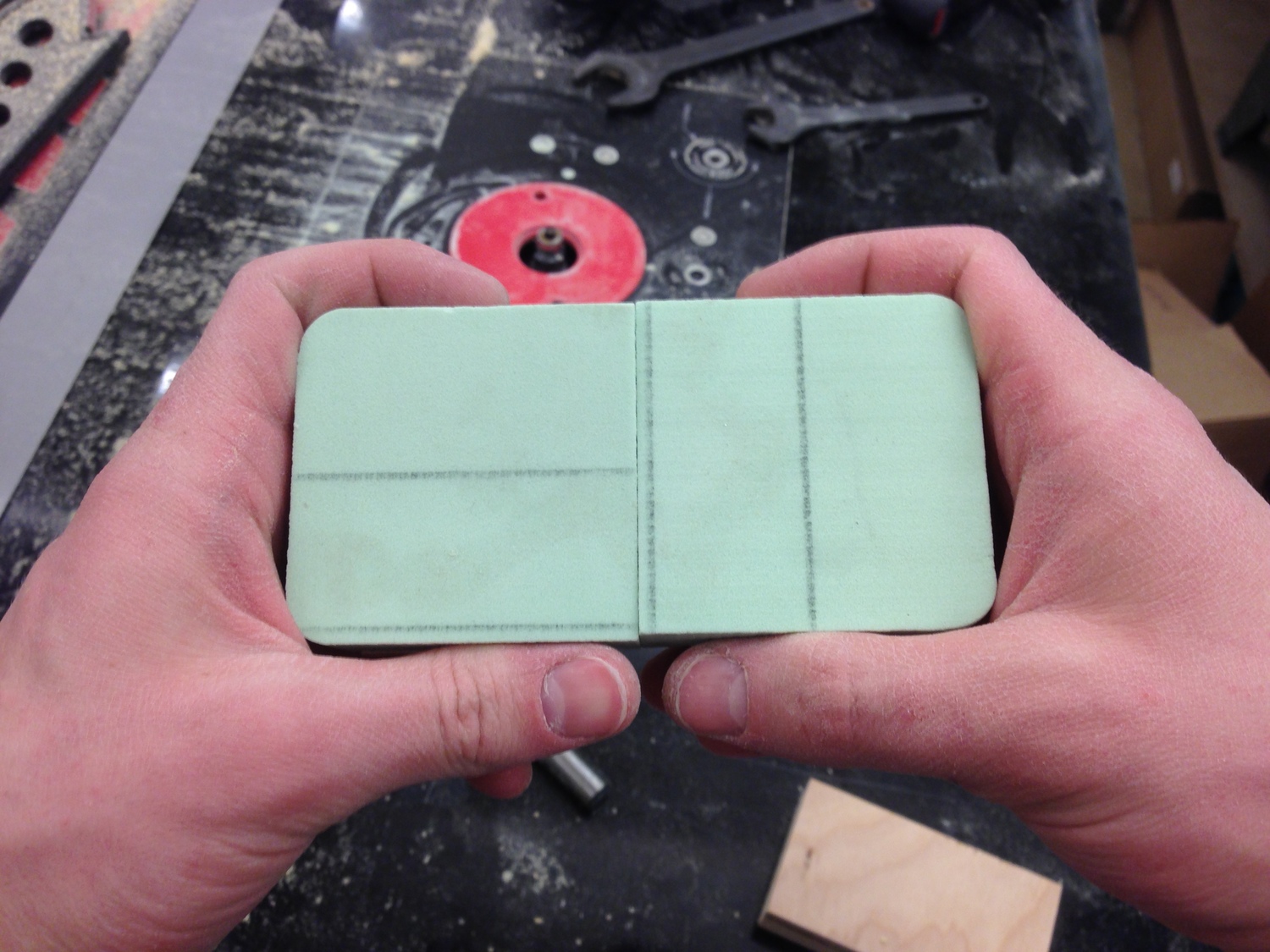

After 4 weeks of focusing solely on the aesthetics on the project and failing to produce a compelling look, we decided to start designing the feel of the product. Using simple wood and foam prototypes we found a size and shape that fit best into people hands.

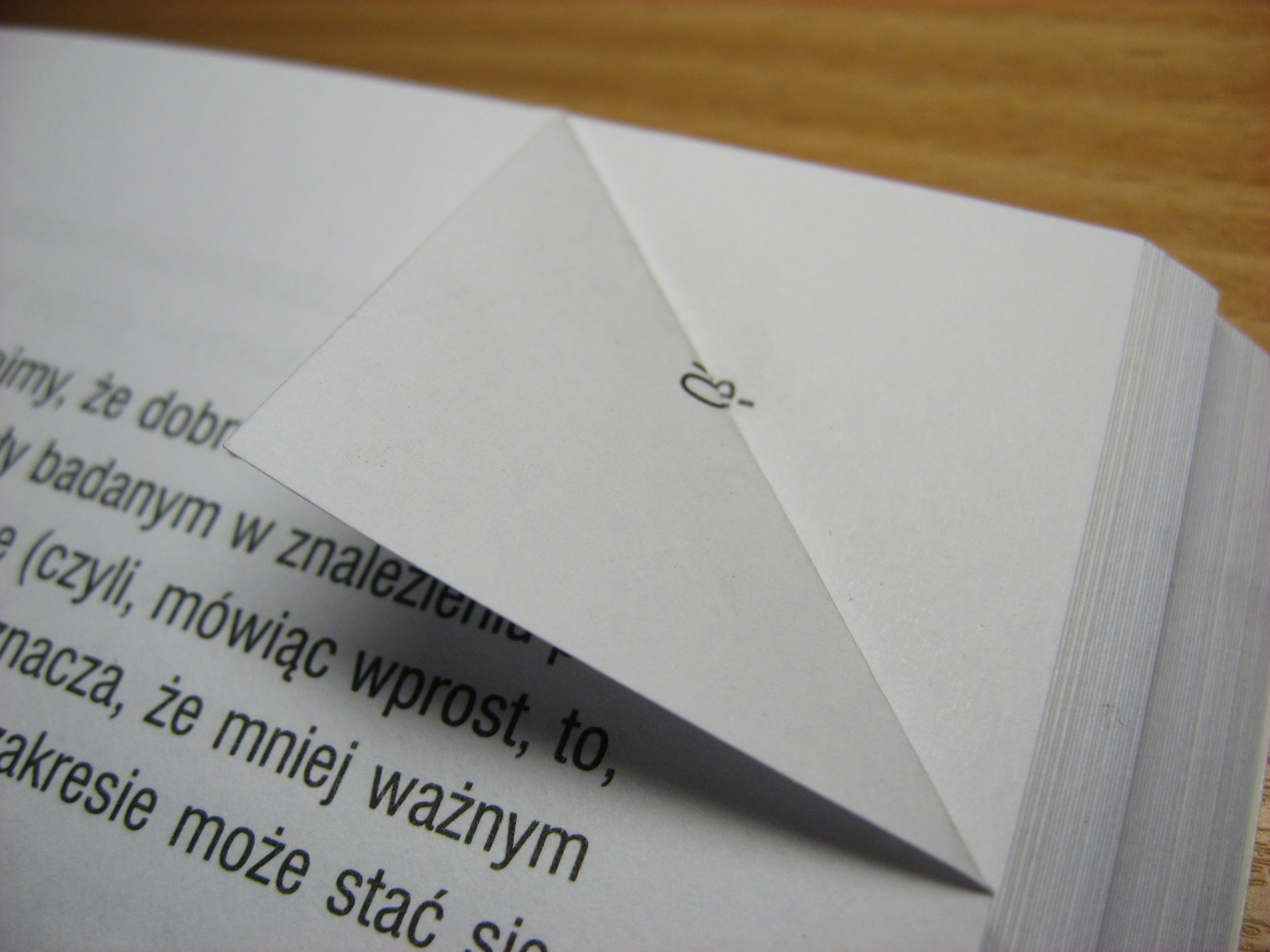

Week 6: Designing the look...again

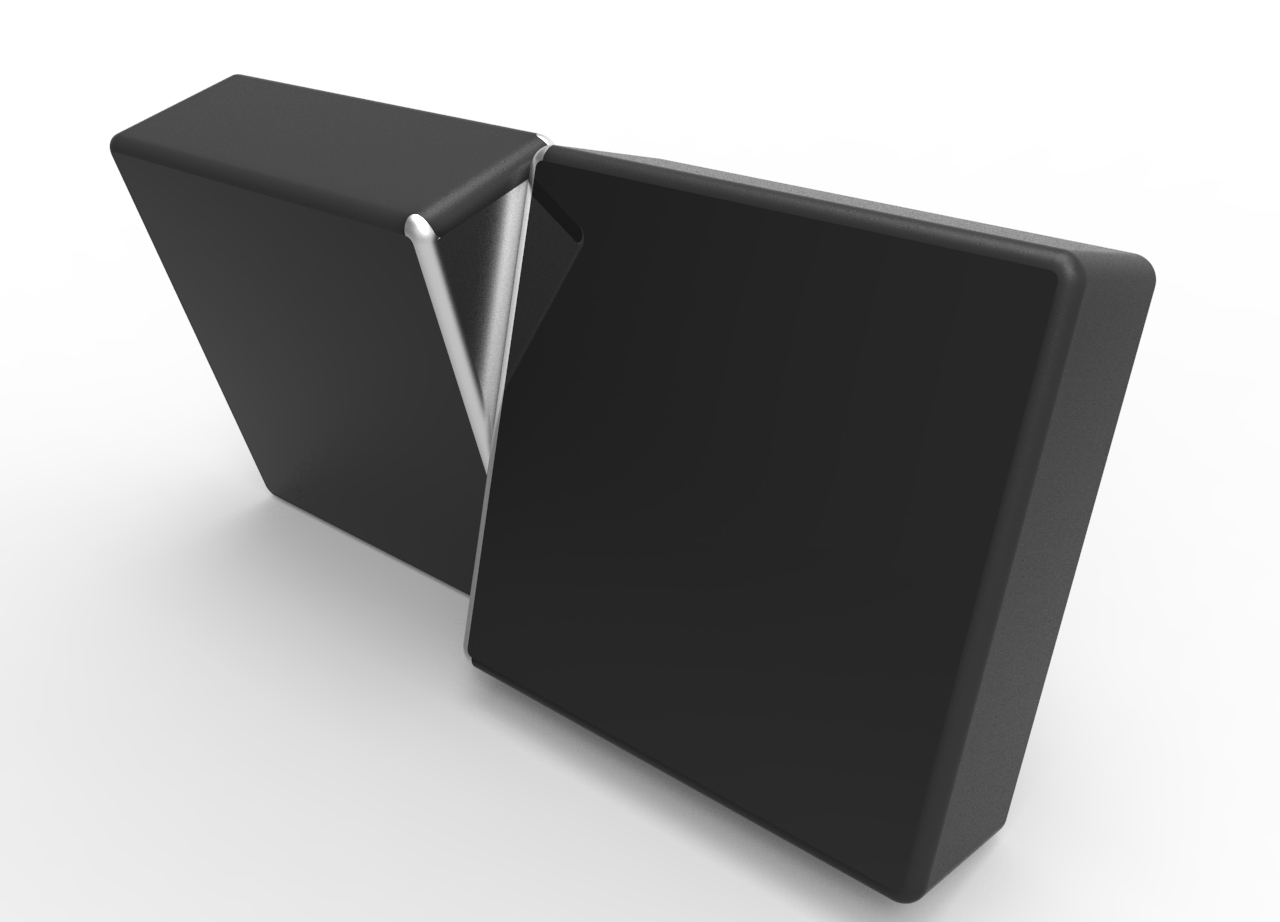

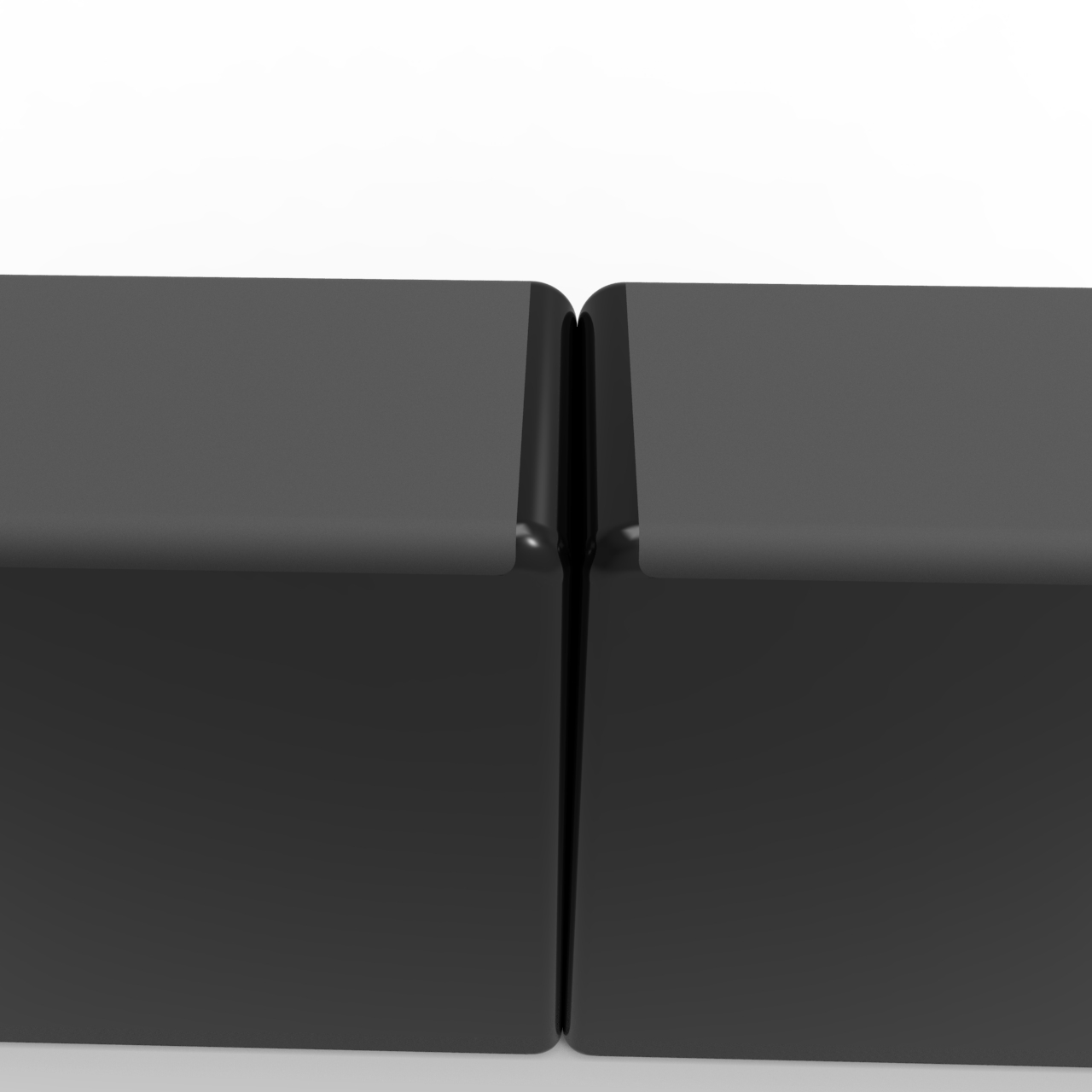

The dog ear inspired the design of the pushback feature, to convey the twist motion to a user.

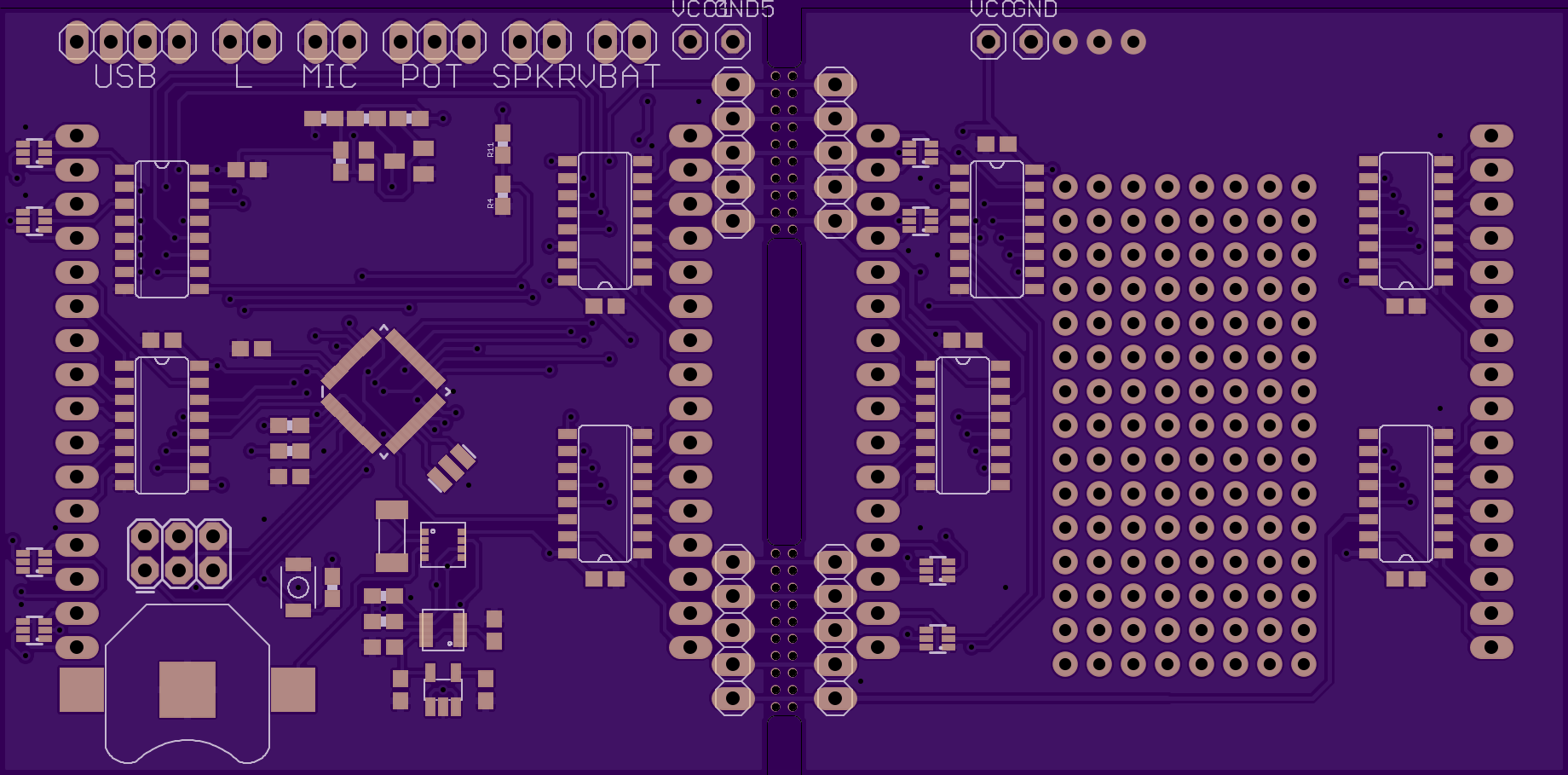

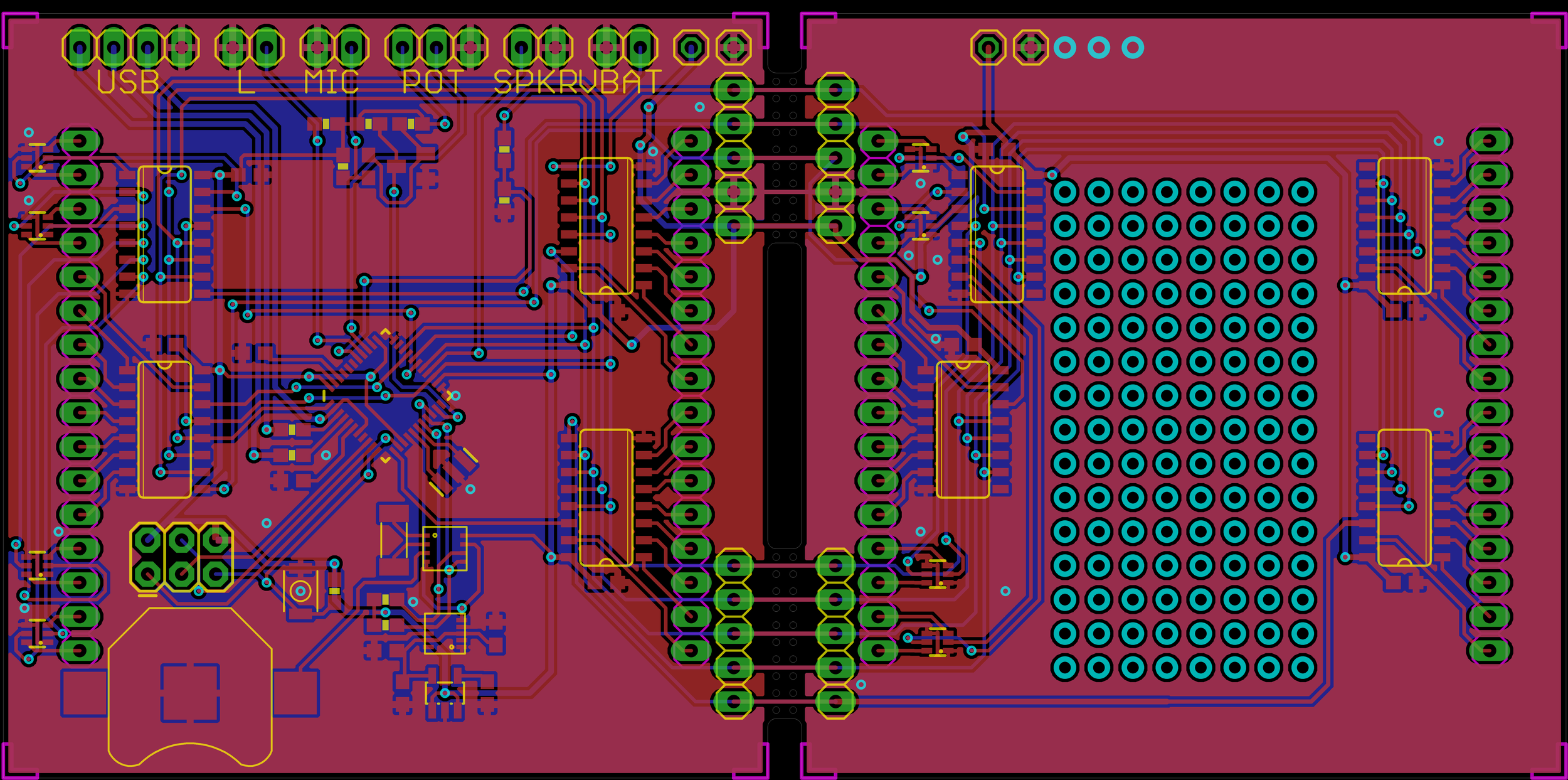

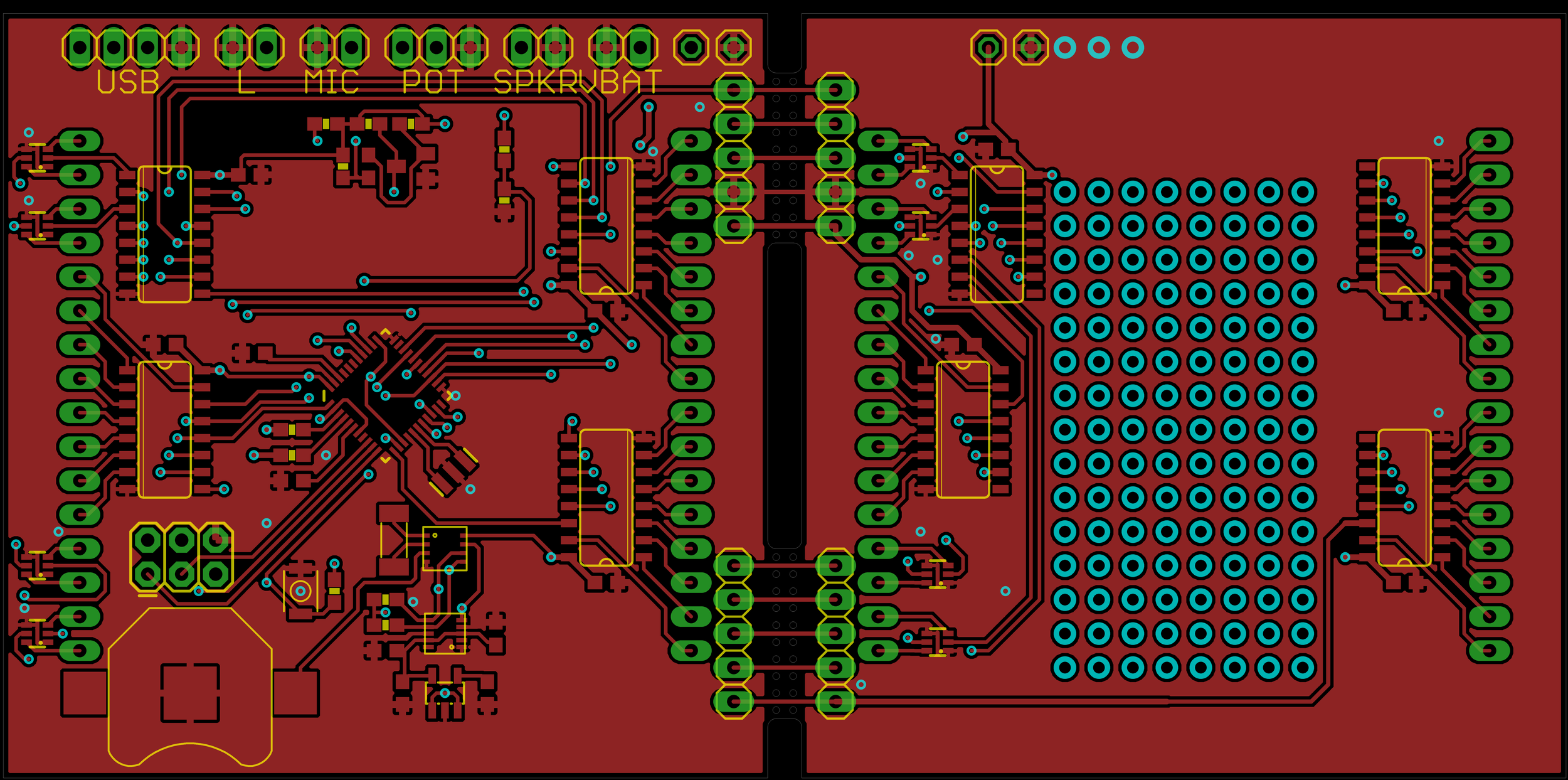

Week 8: PCBs are finalized

After debugging the previous boards designed by Kevin and revision was sent to a fab in Boulder, CO called OSH Park. The boards are designed with the addition of a prototyping area to allow users to easy customize the hardware.

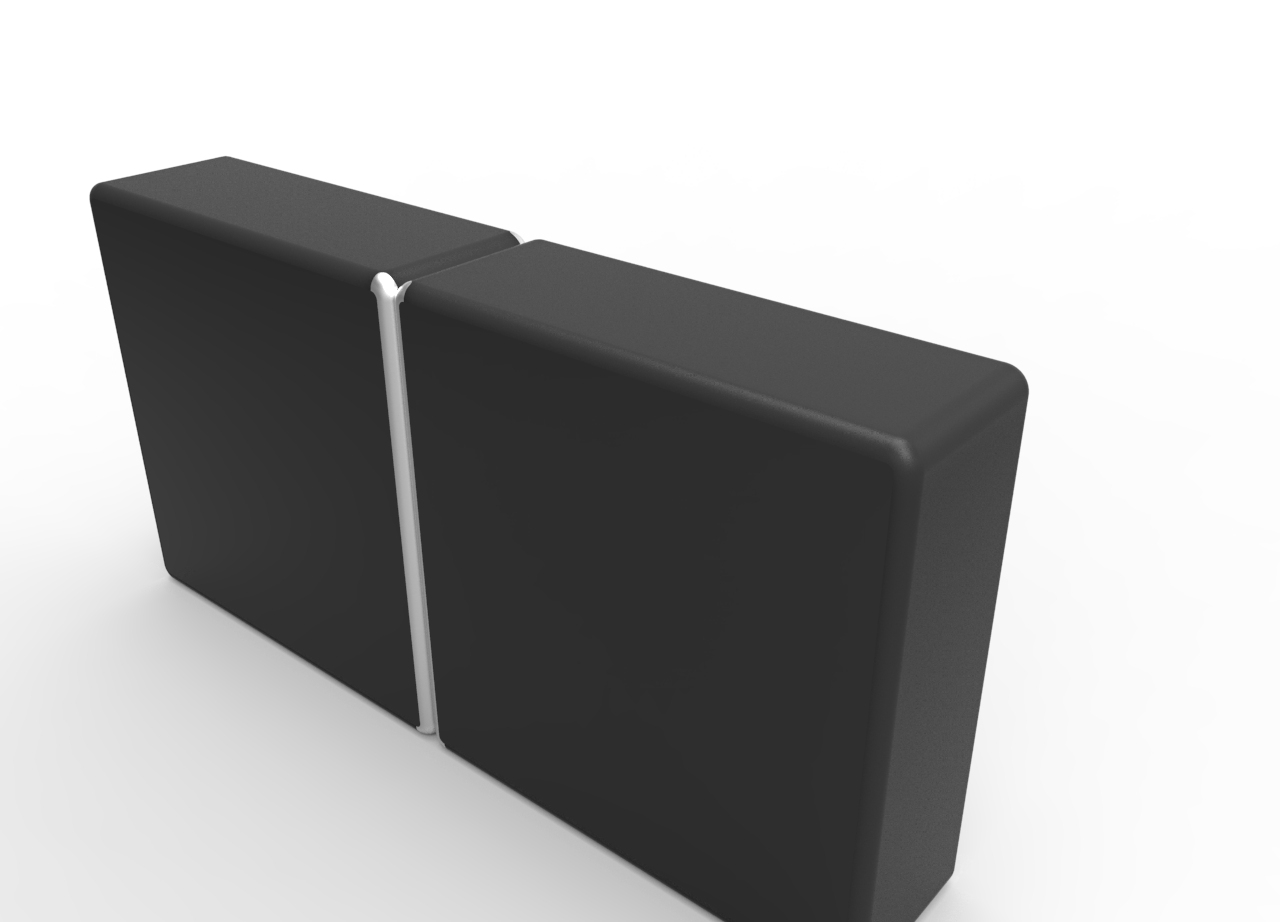

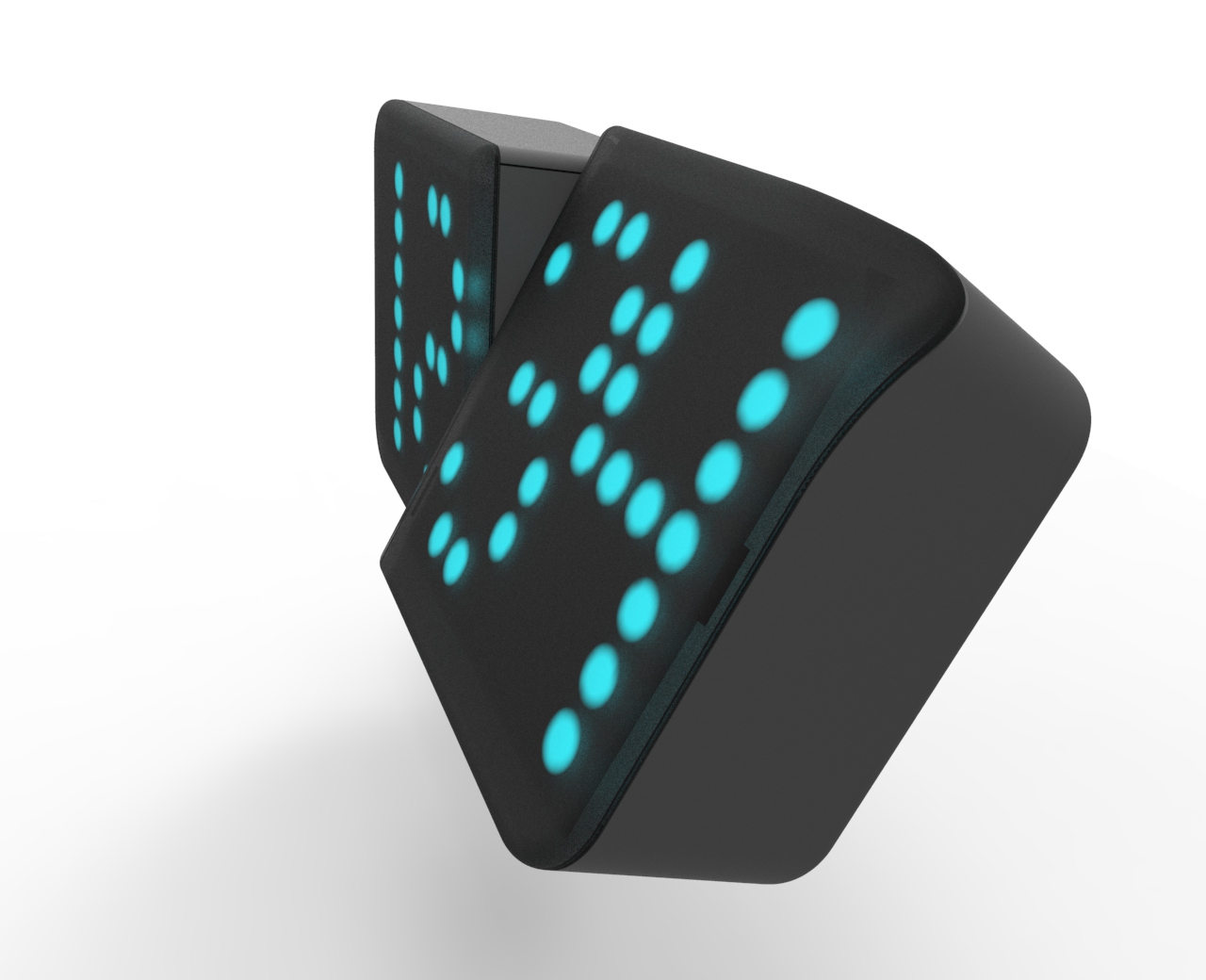

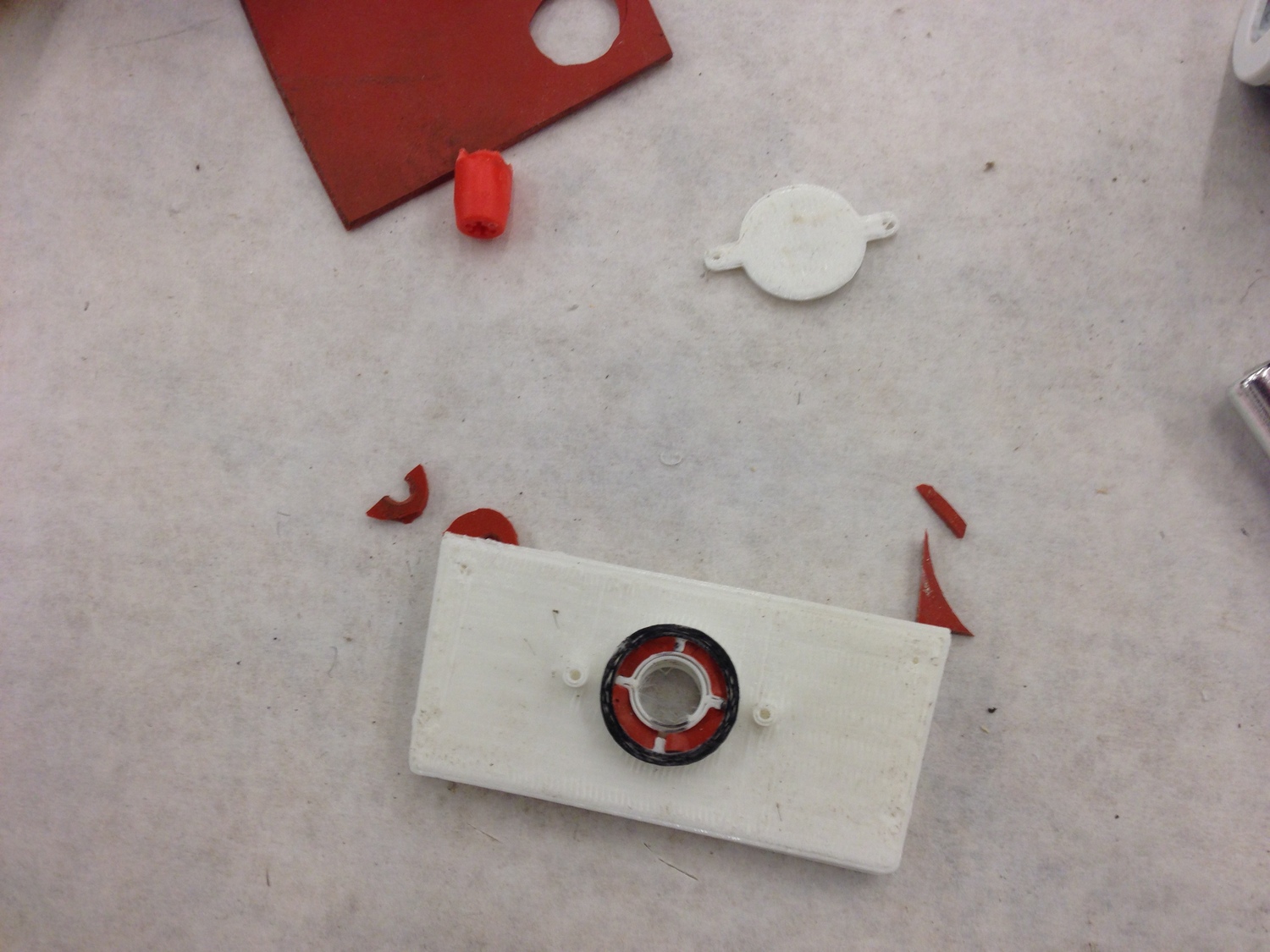

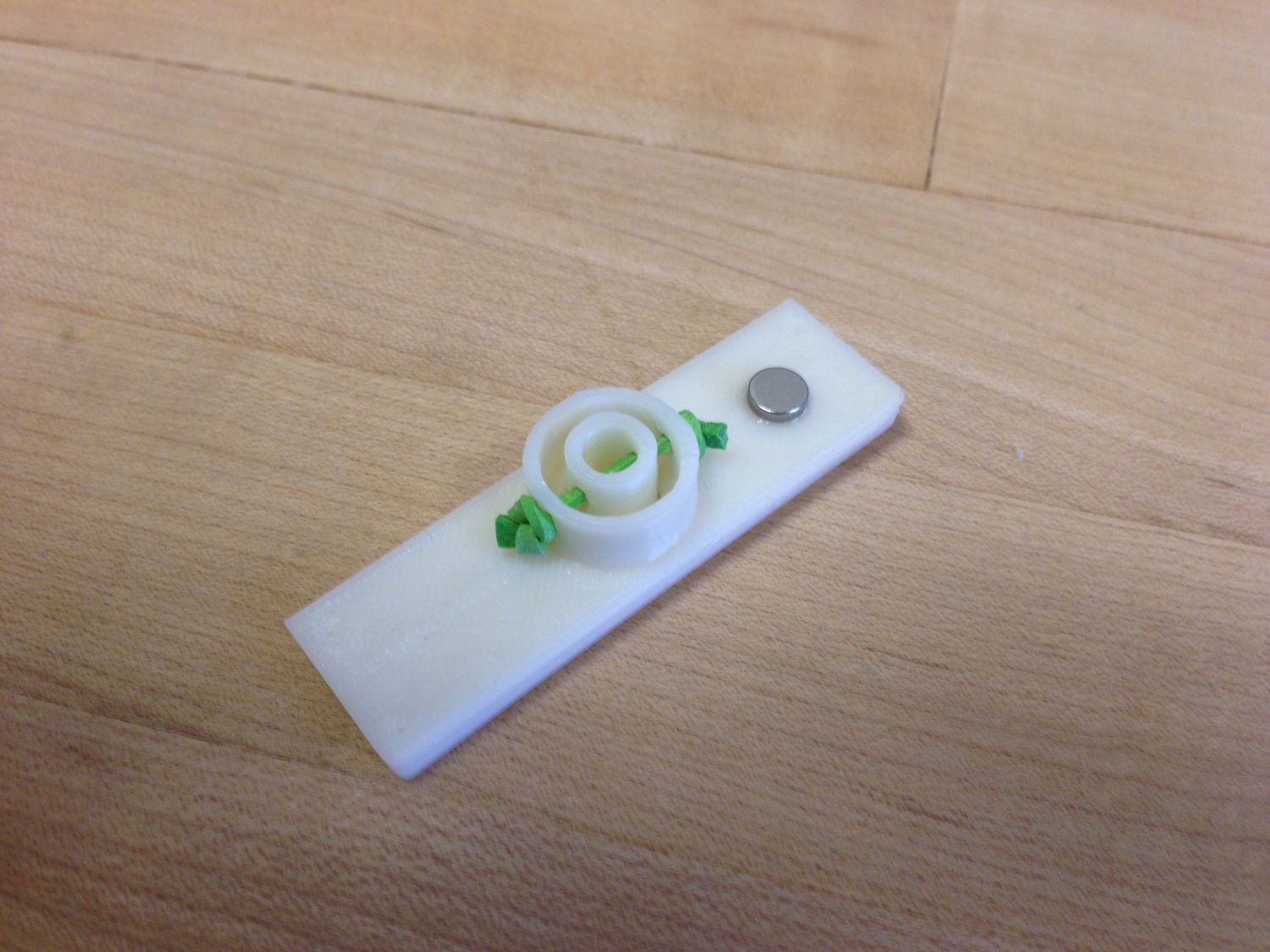

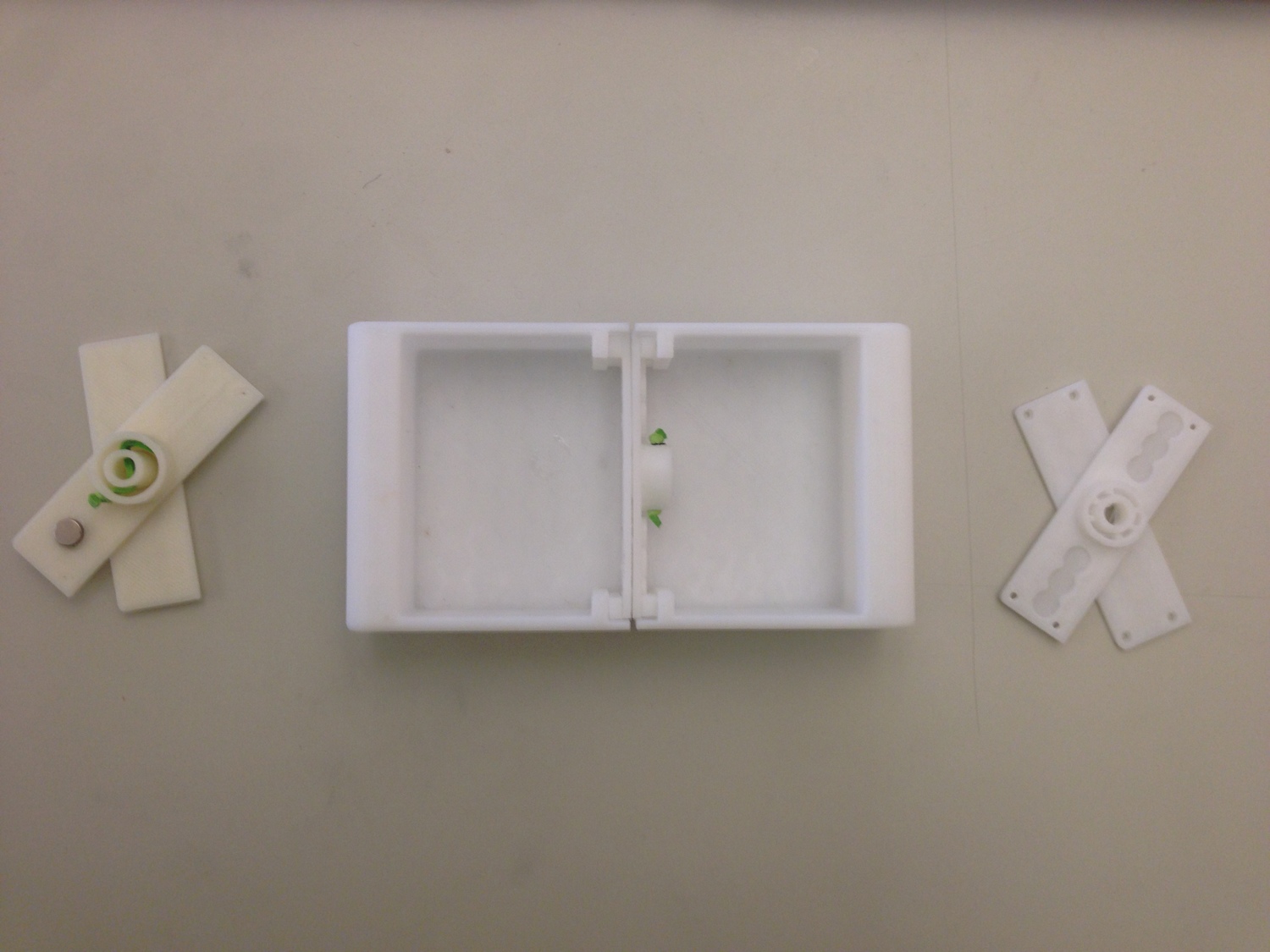

Week 7-9: Mechanical Twist 1

Most of the month of march was spent working on the twist mechanism. Two concepts were explored using high strength rubber. One used the rubber in compression, while the other used it in extions. The inspiration for this came from car bushings. Due to the strength of our 3D prints the compression method could not used, so settled in the extension design.

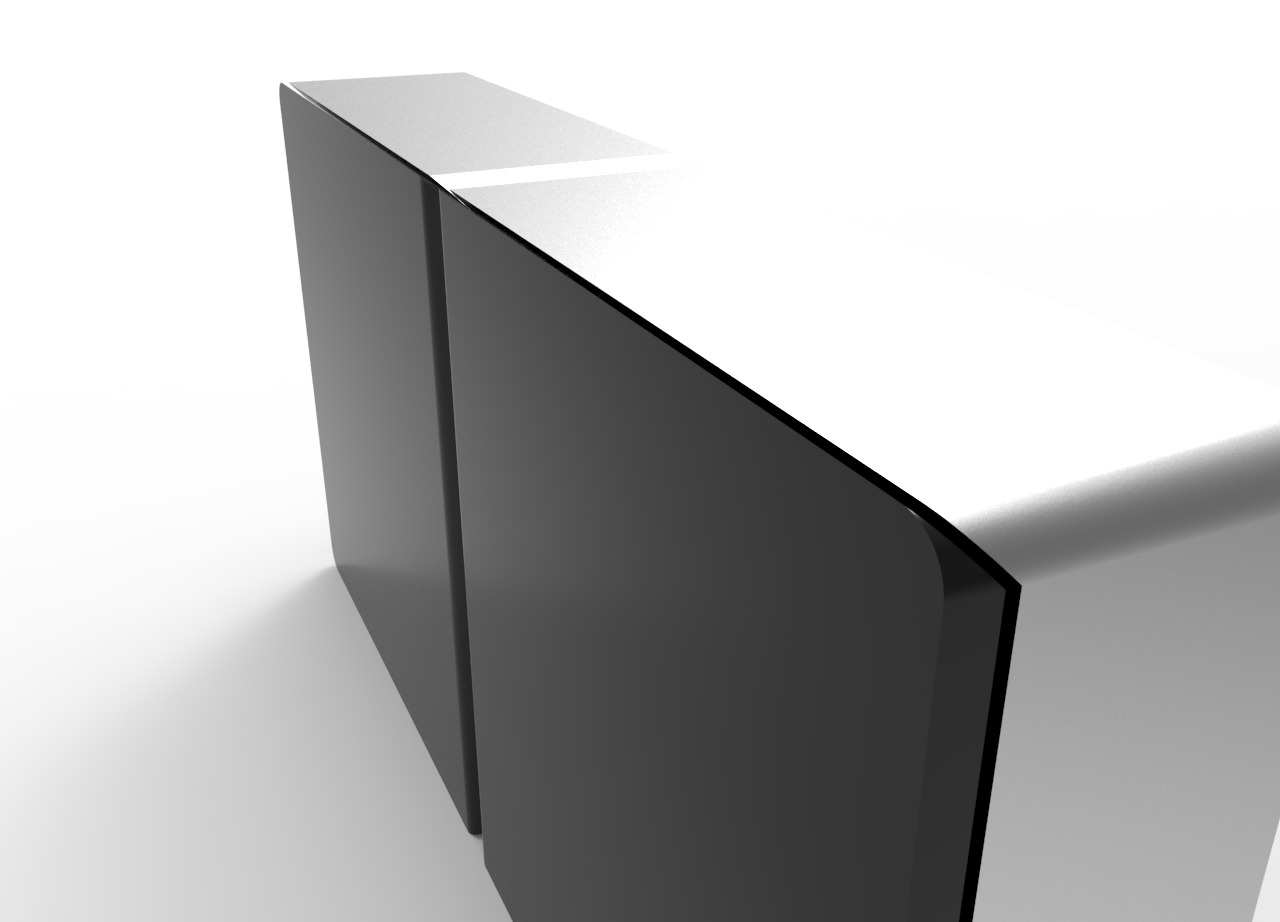

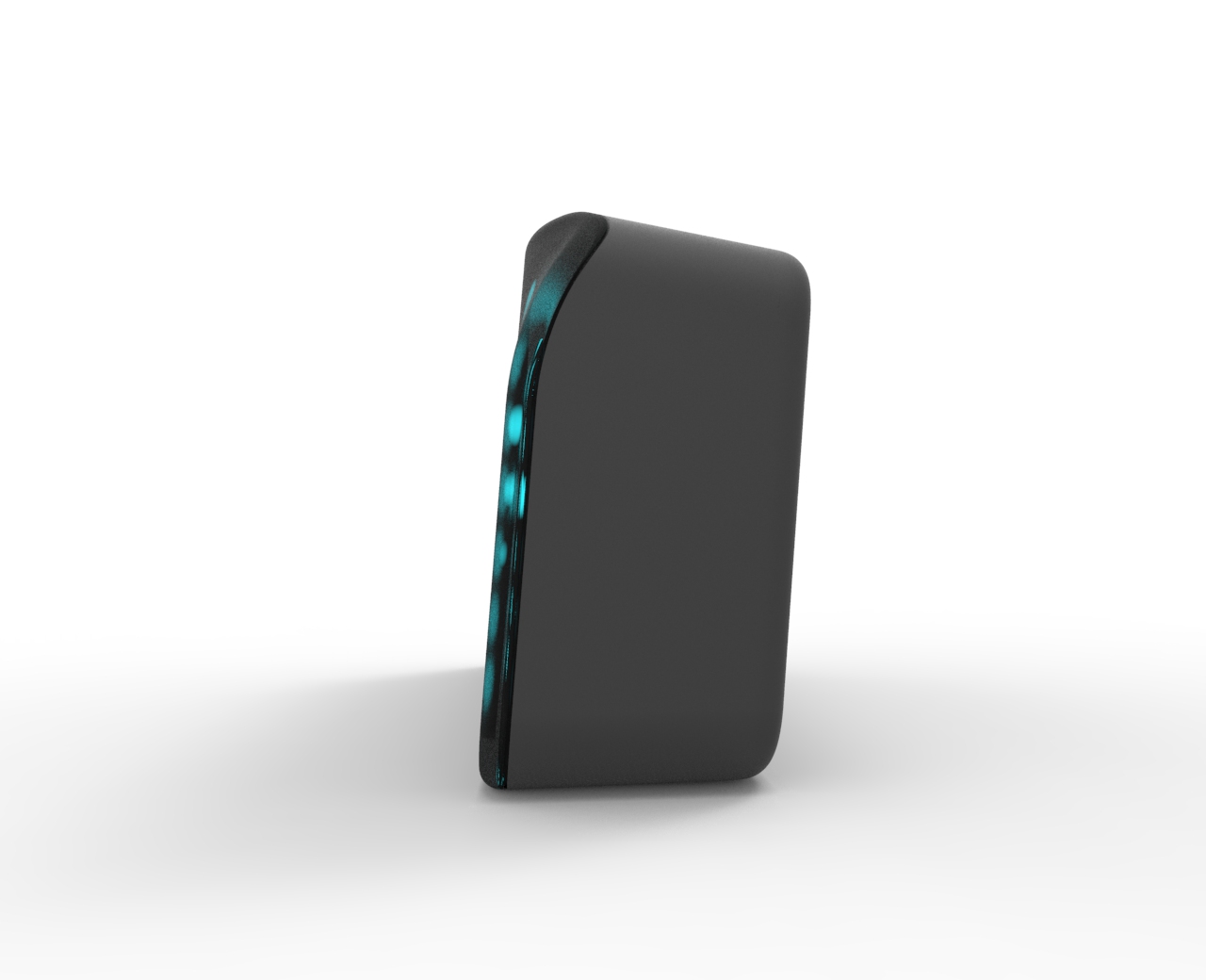

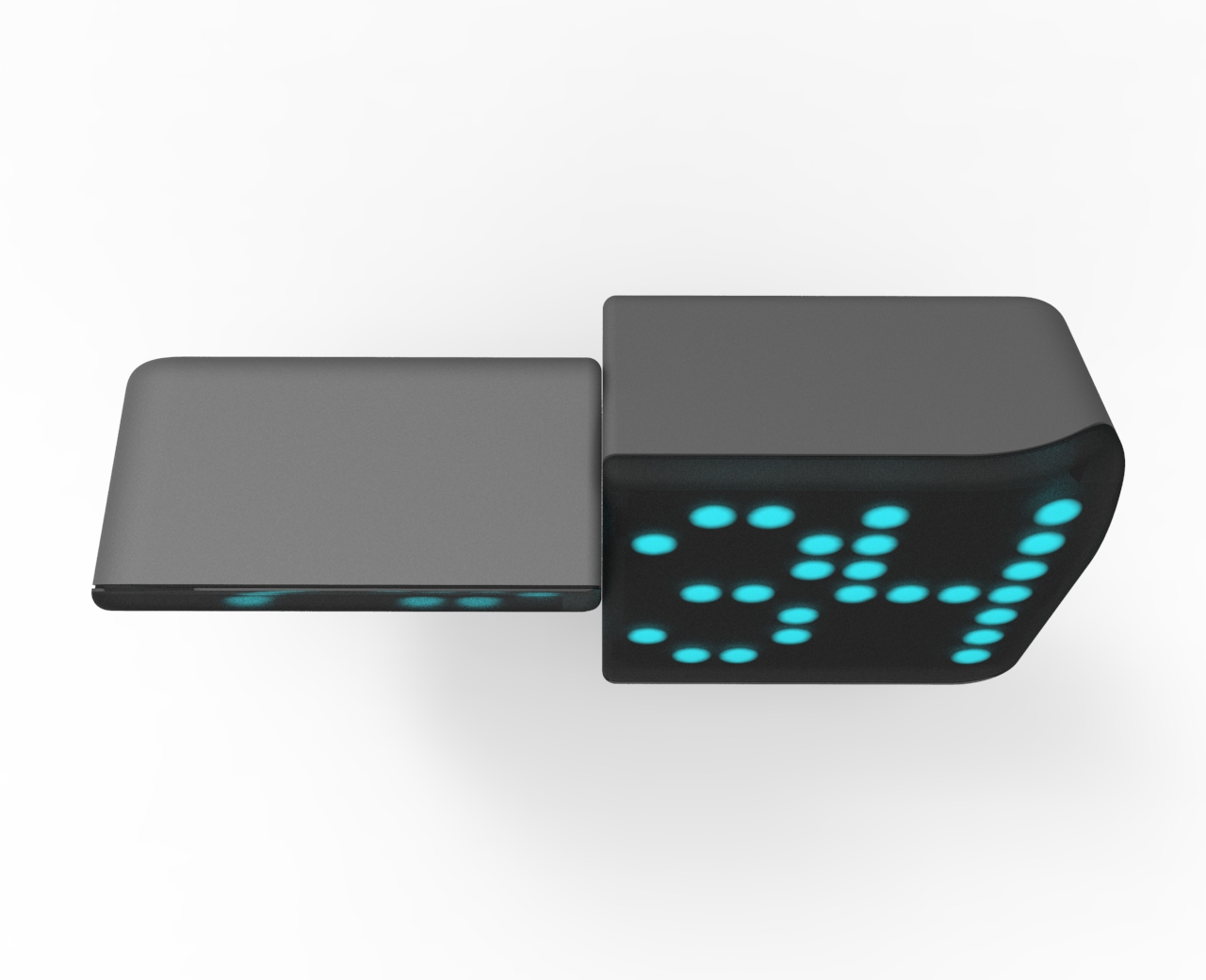

Week 10 & 11: PCBs arrive from OSH Park and join the Shapeways prints

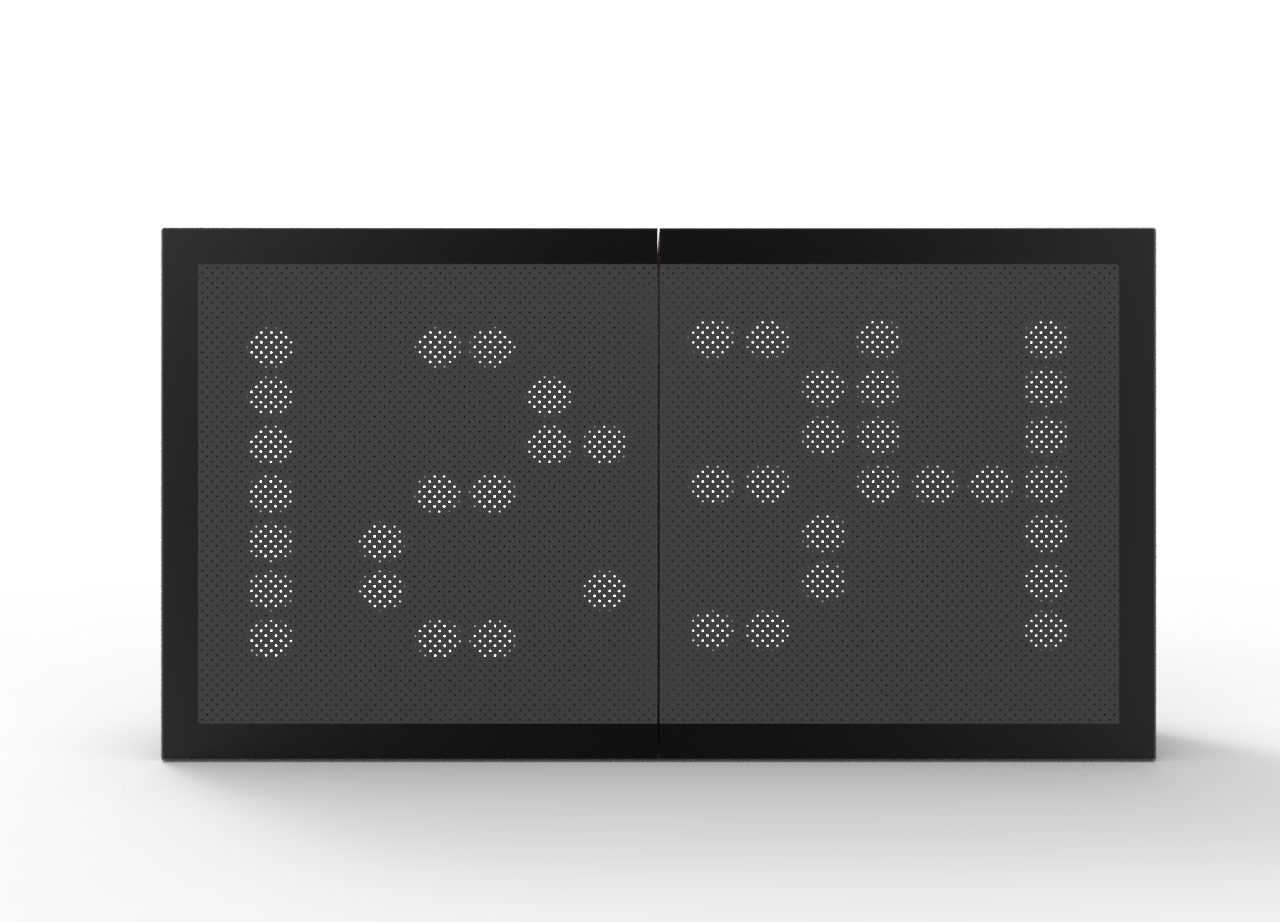

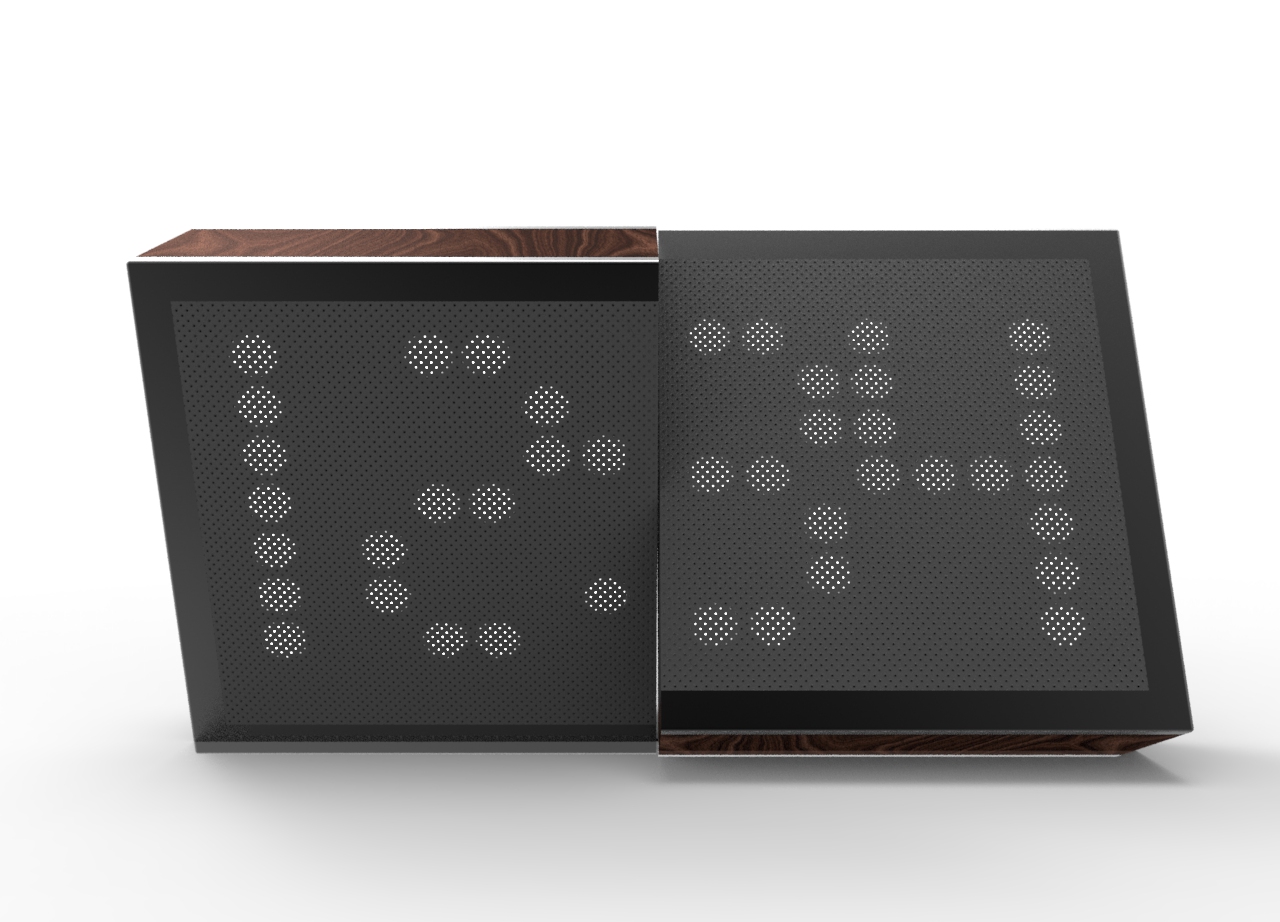

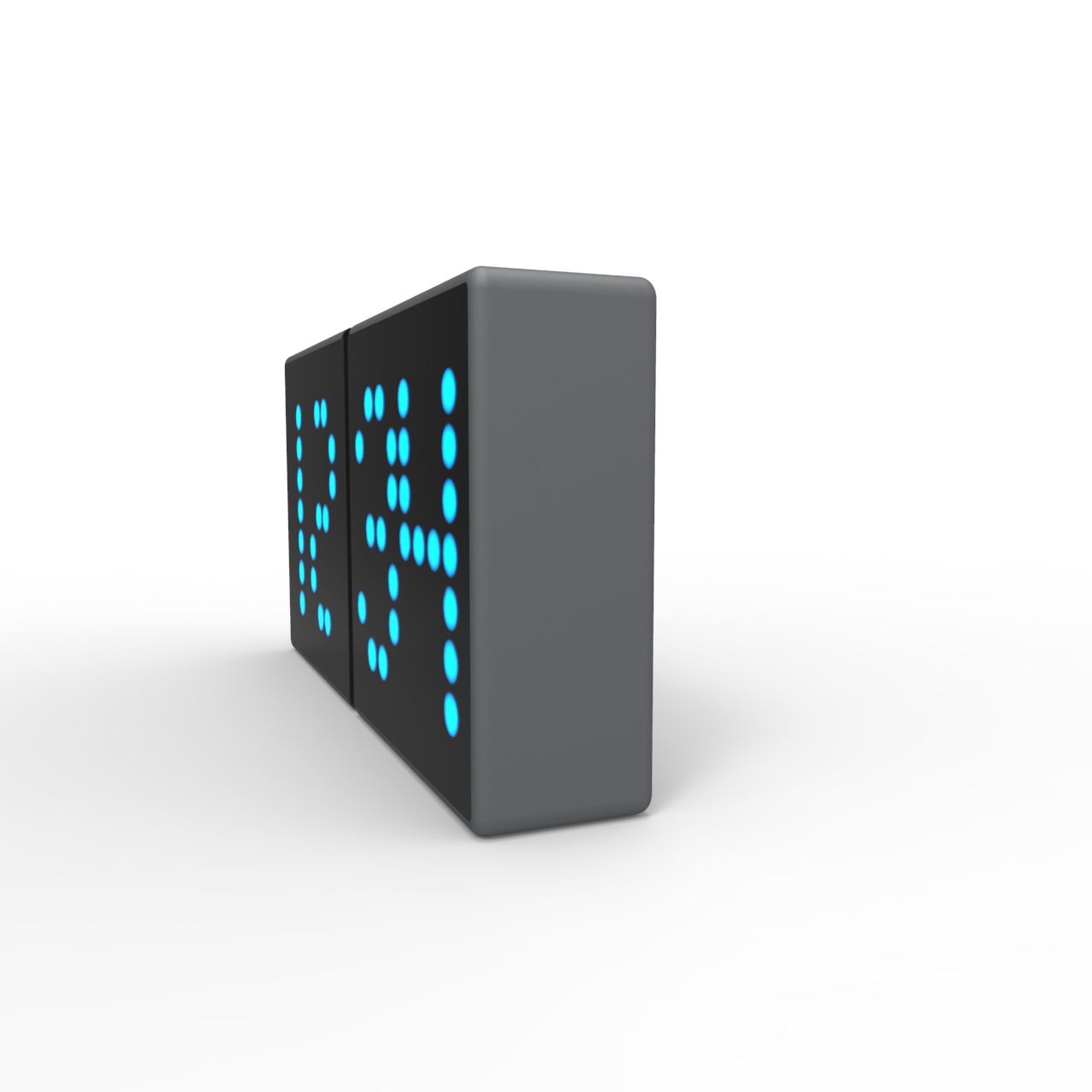

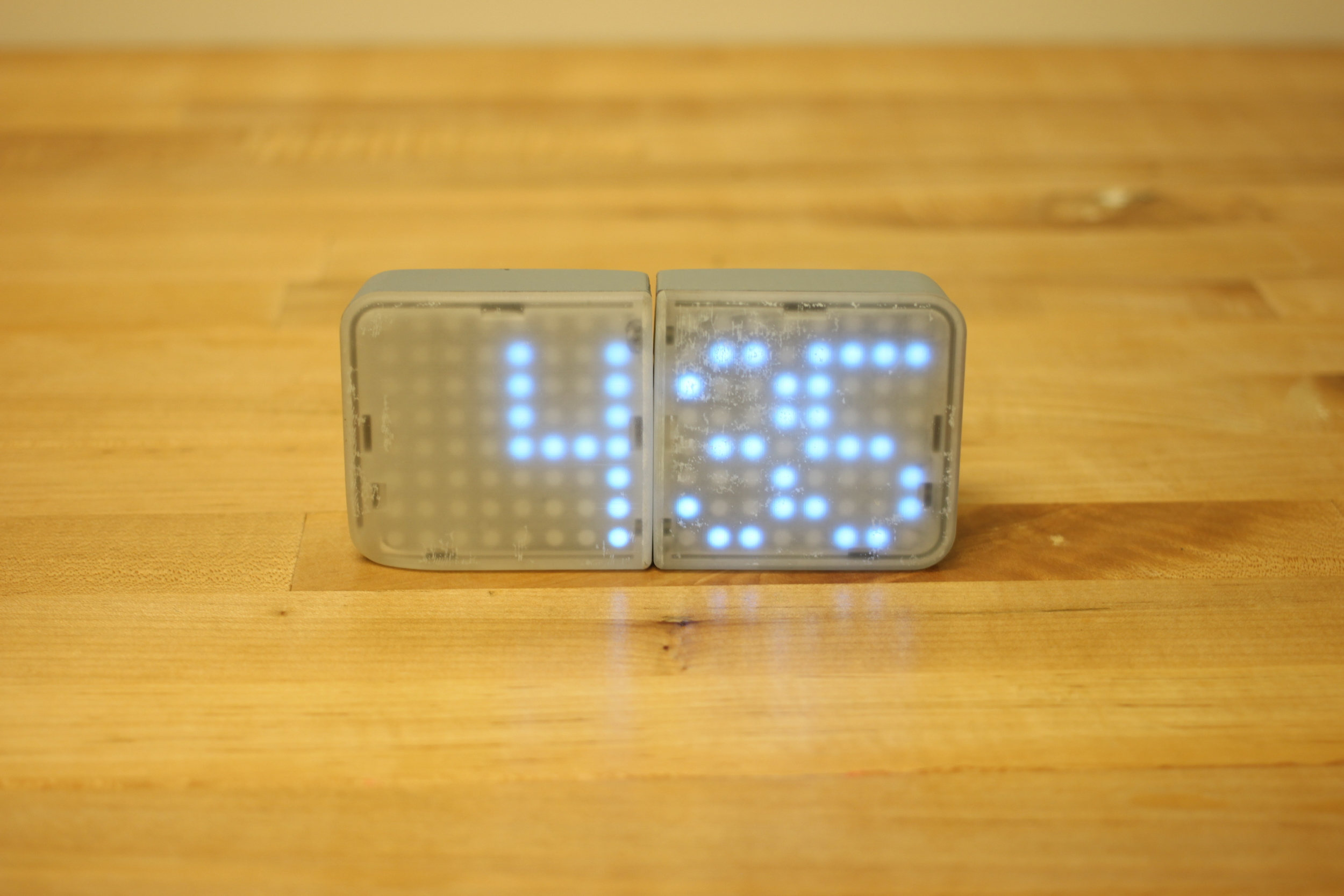

In preparation for the presentation and demo for Quirky all the parts are coming together to form the first working prototype that reflects the new form.

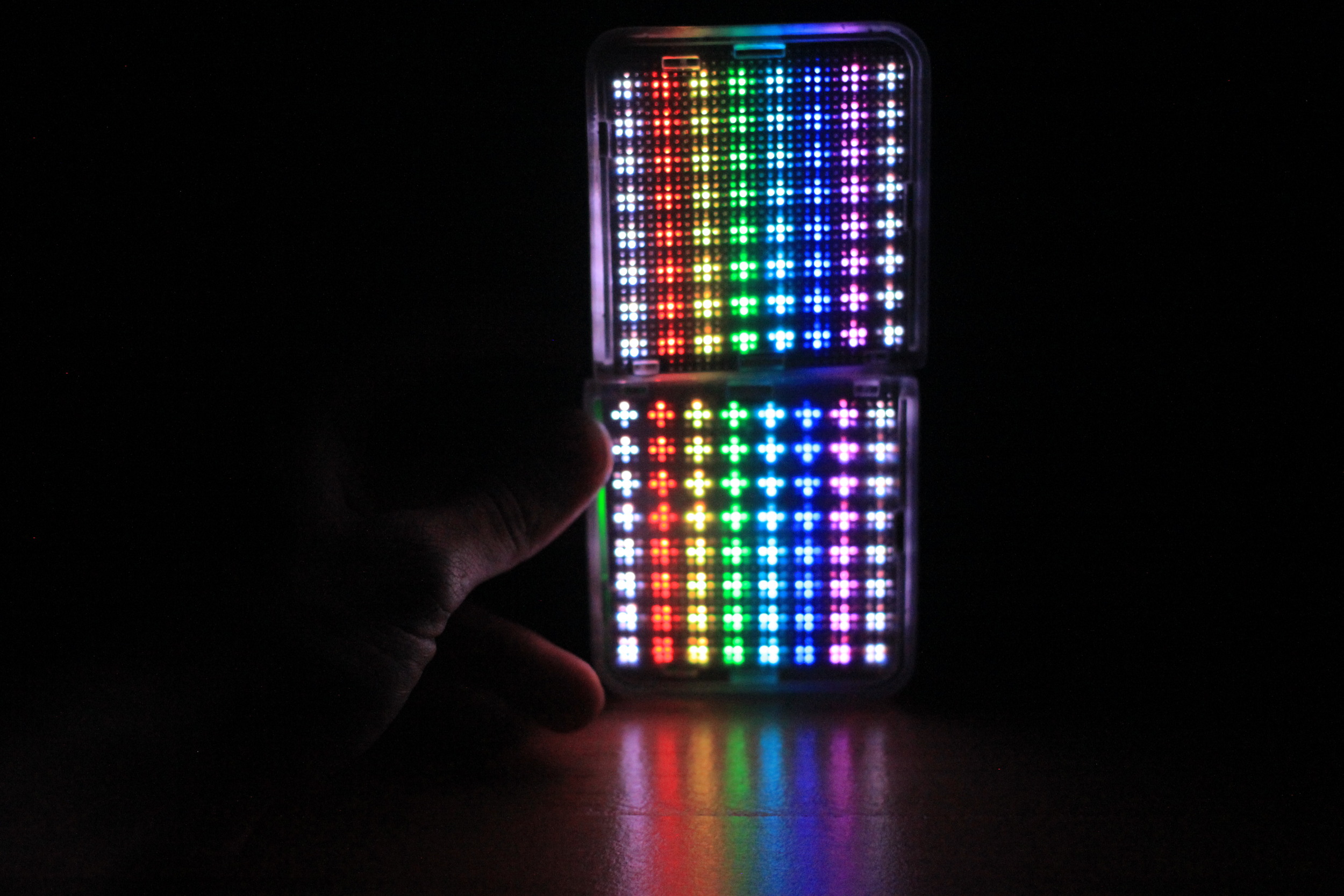

Week 12: The first prototype is completed

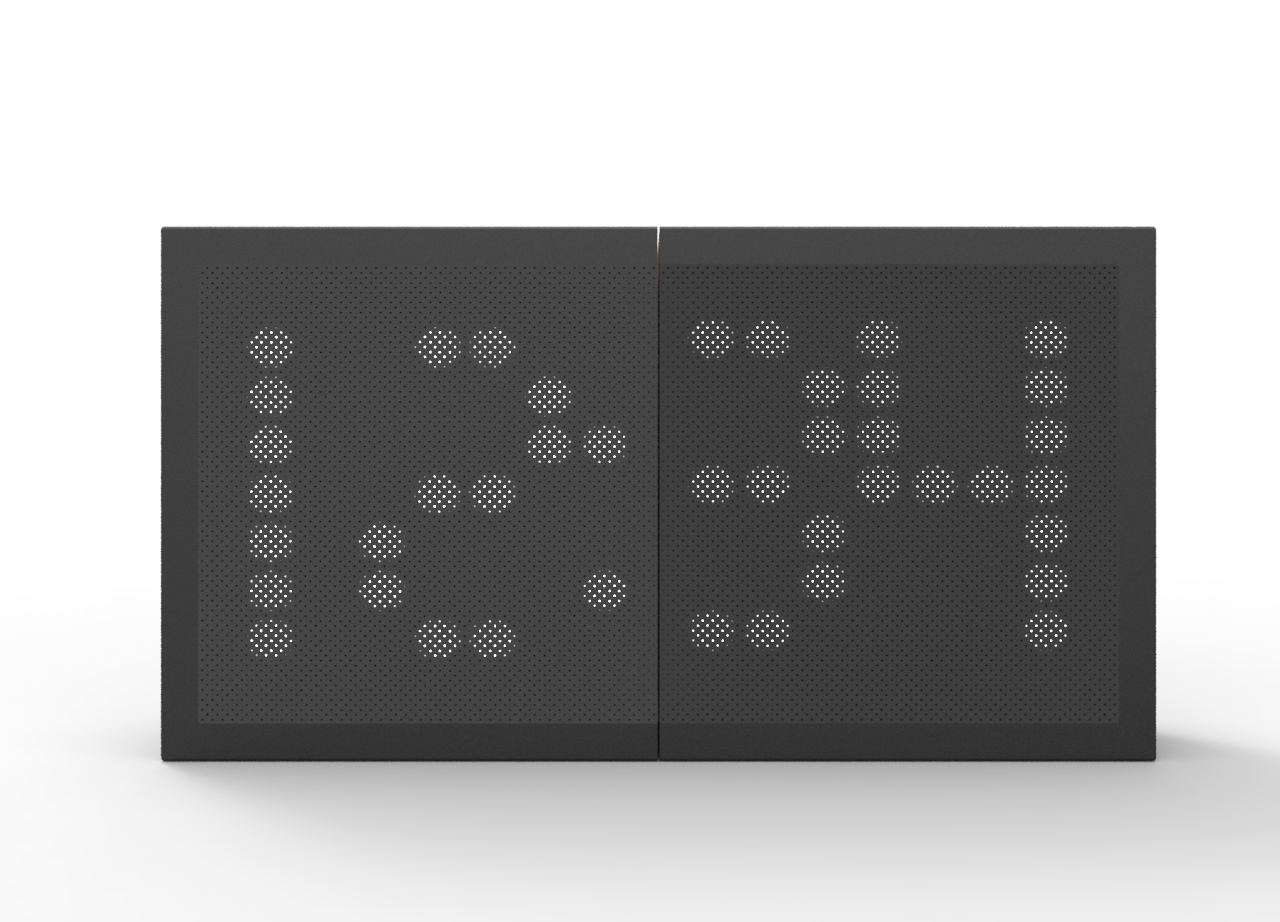

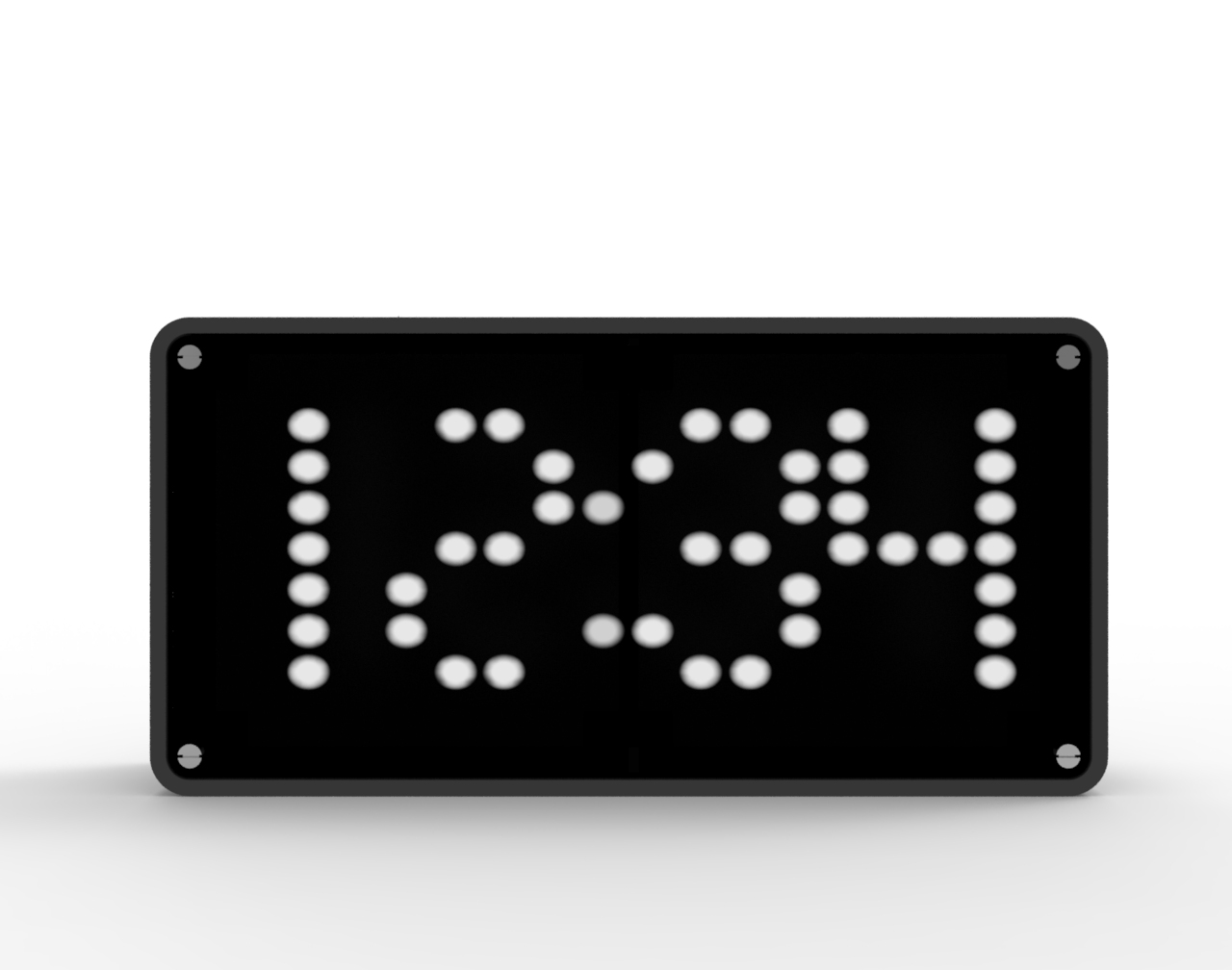

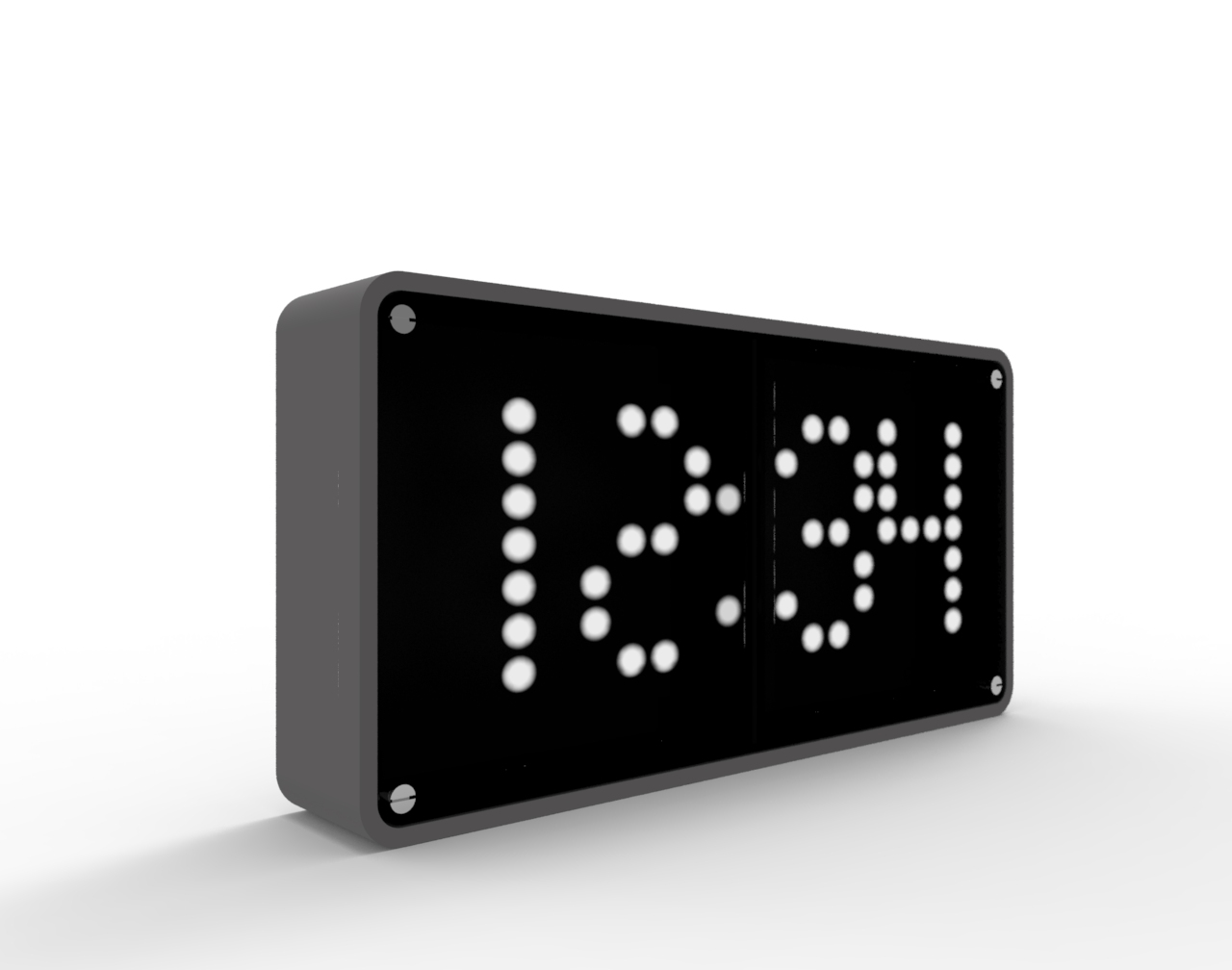

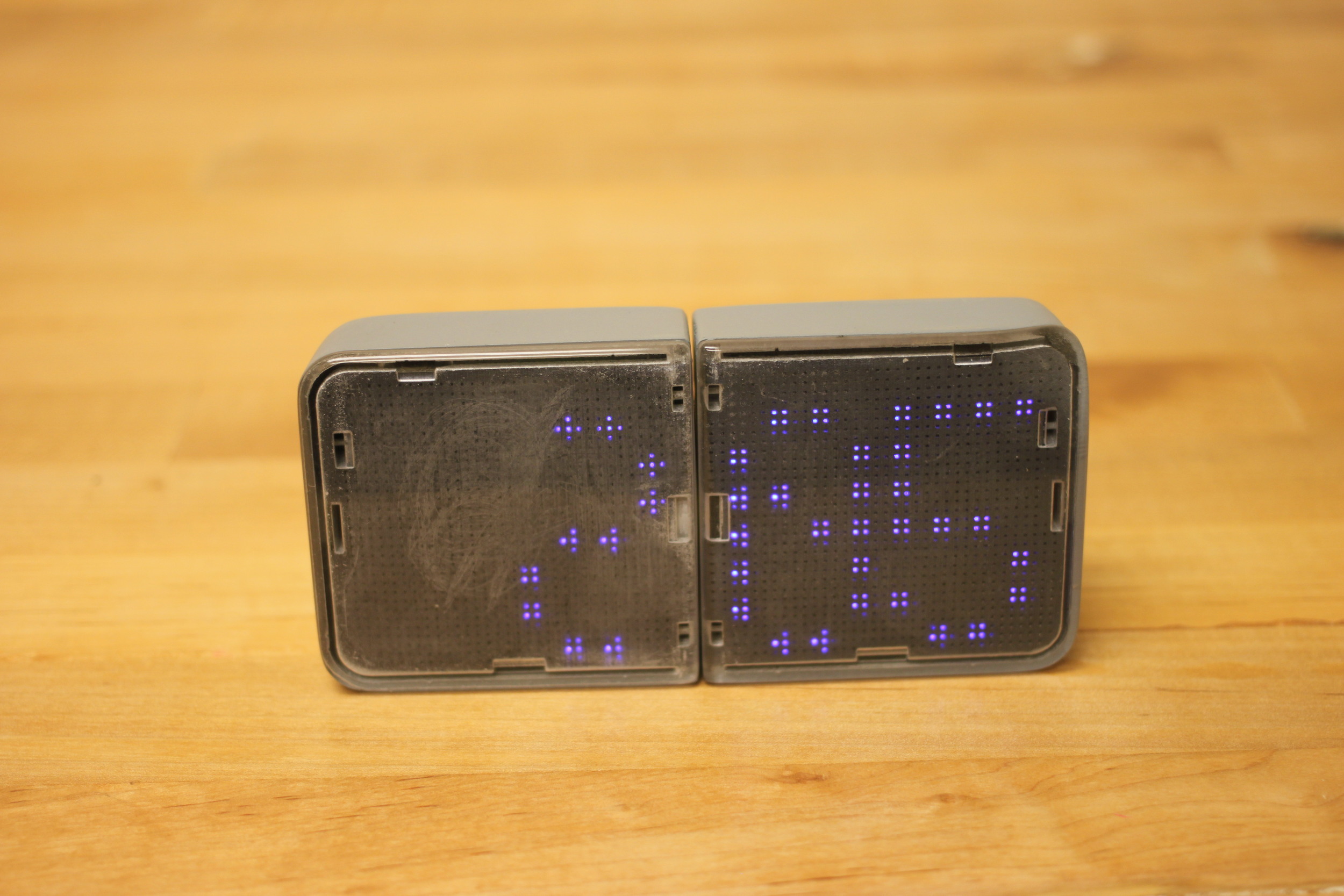

The first prototype was fully function, but we got great feedback involving the legibility of the numbers.

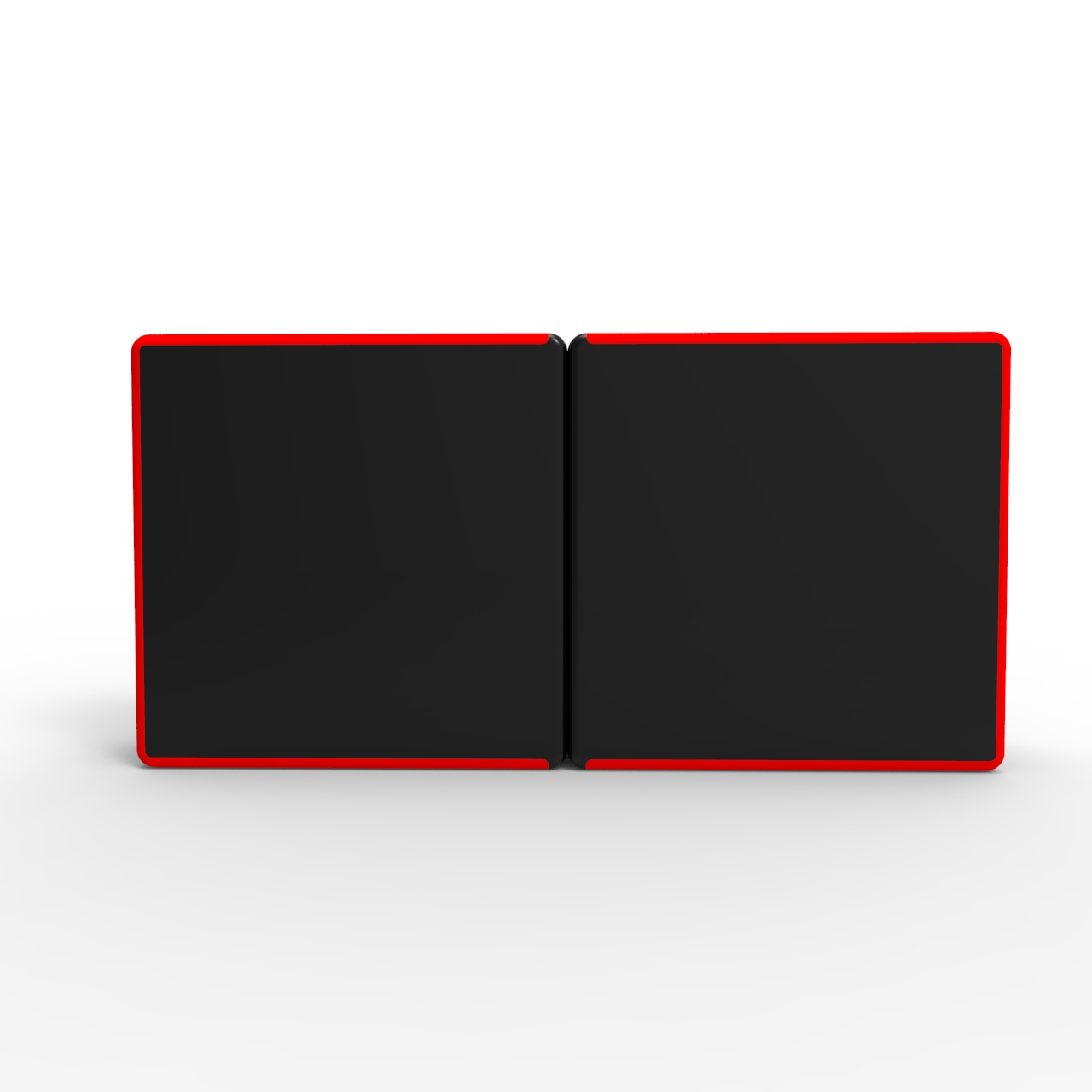

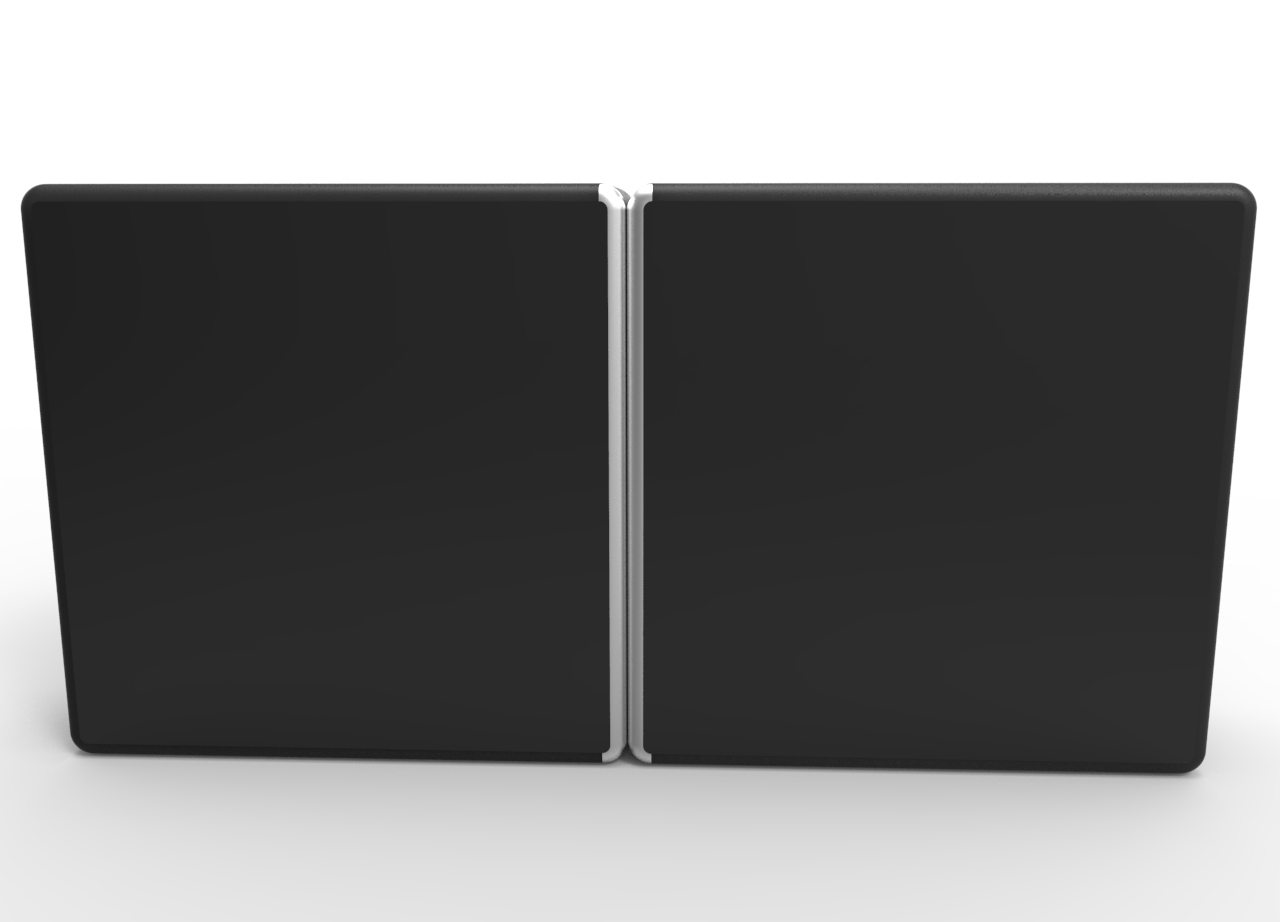

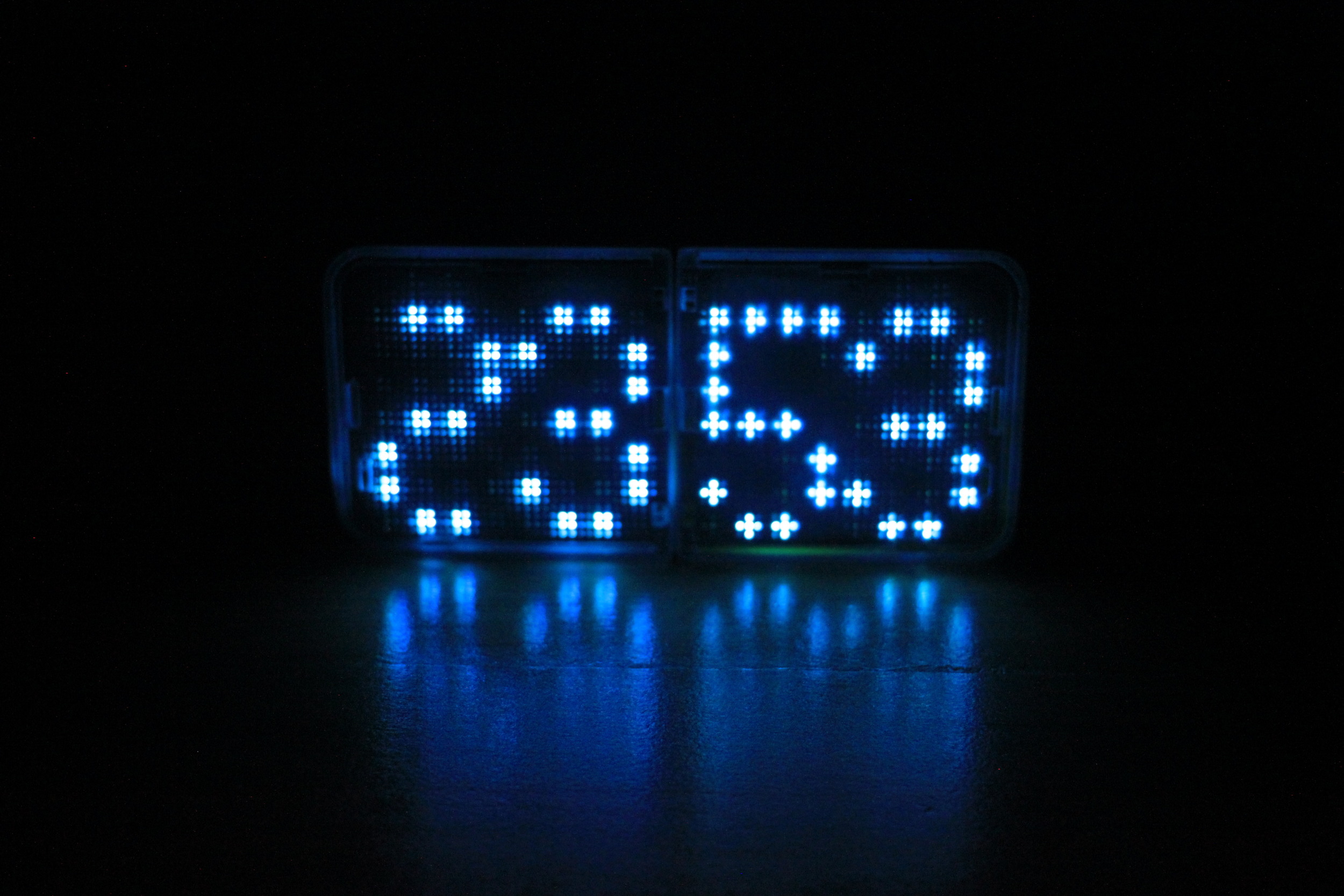

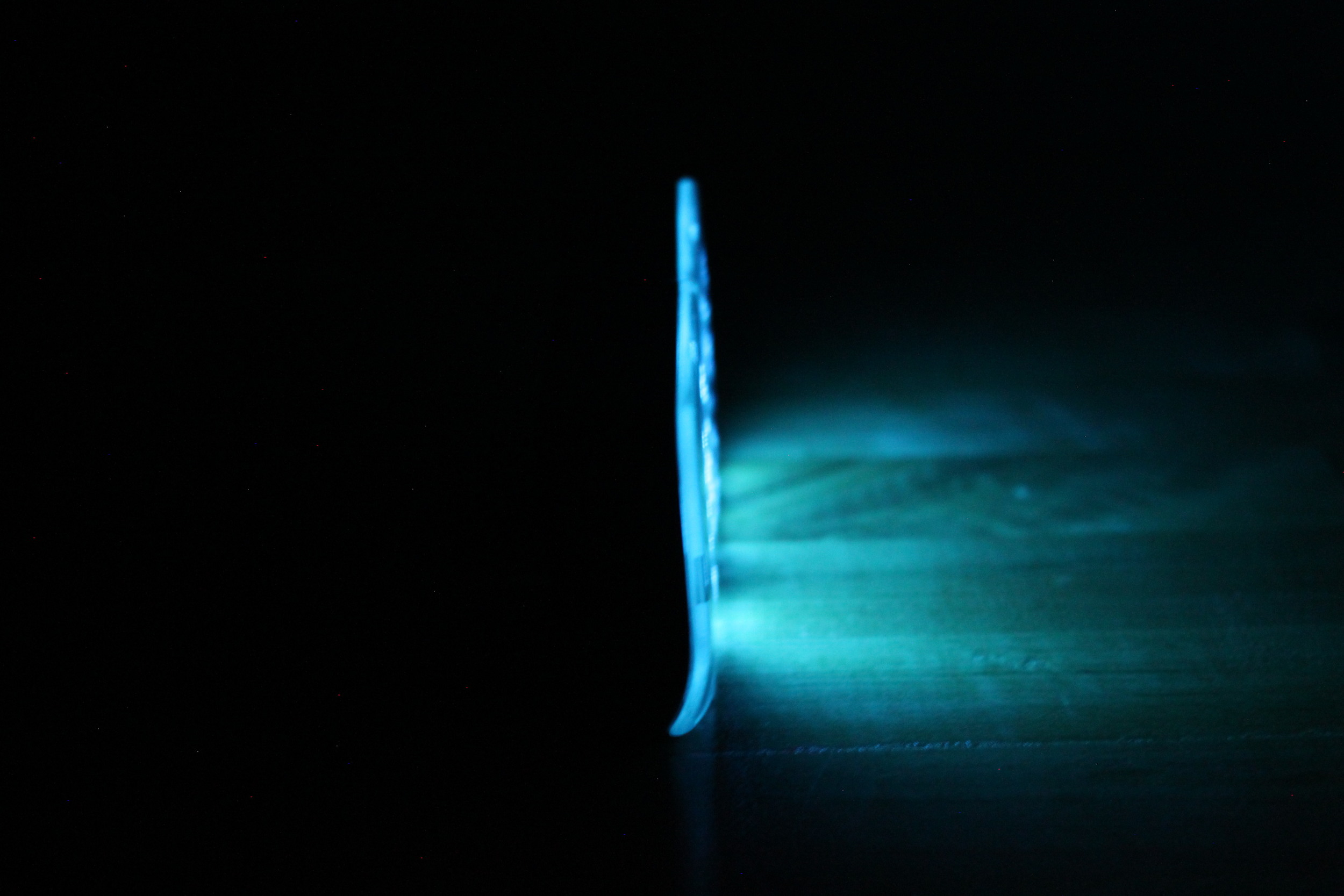

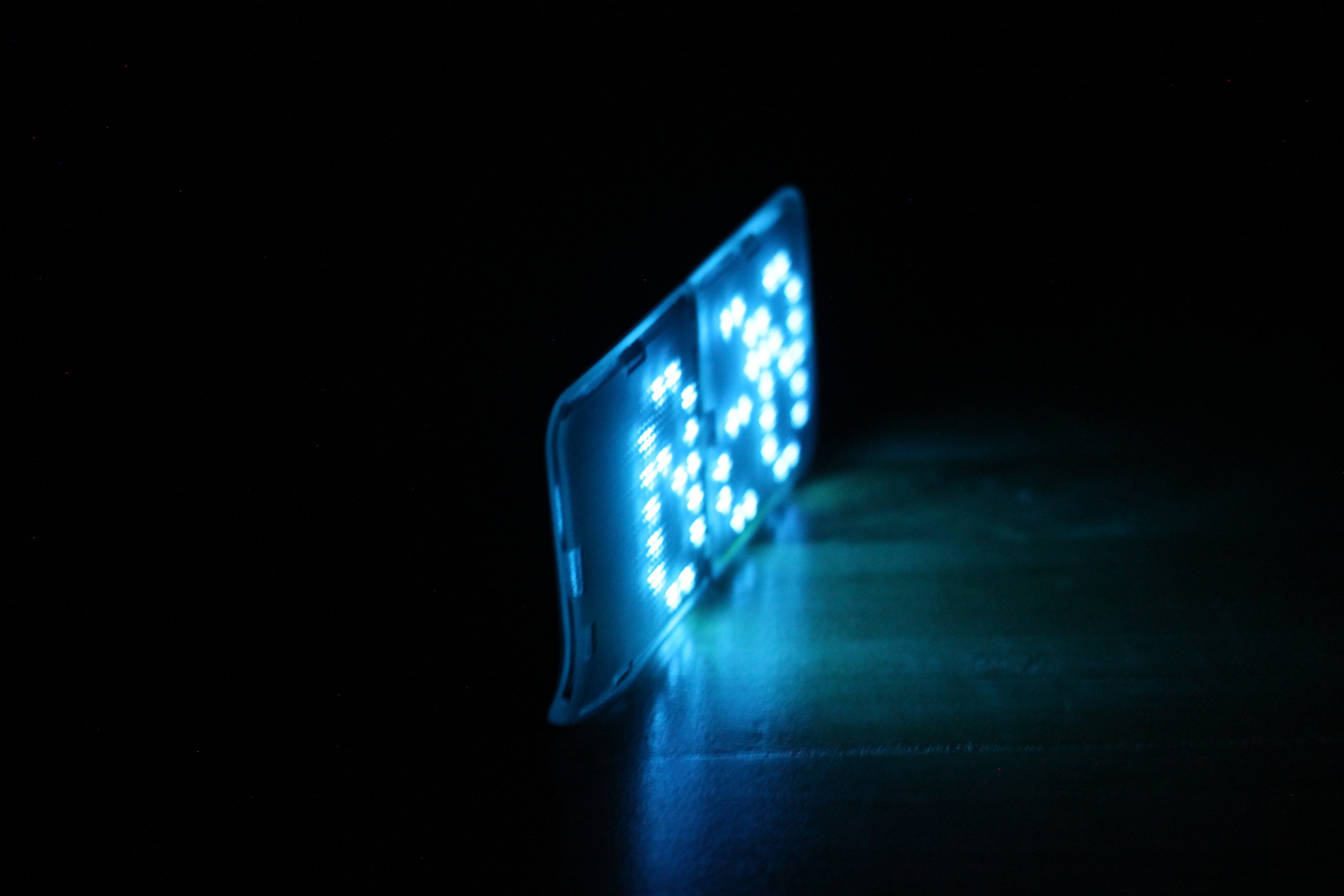

Weeks 13 & 14: Final prototype

Using a new 3D print that was polished and a screen made from laser cut paper we experimenting with different and how it can better the legibility of the screen.